Water Transport Solutions

Erstatningshavn Færgehavn Nord, DK | 2021

Download the full case study

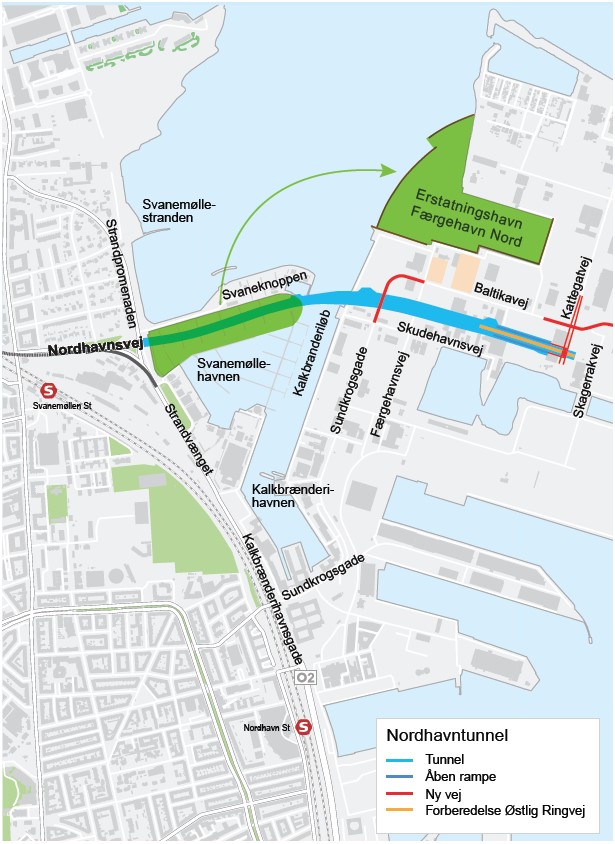

As the tunnel is to be built with the cut and cover method, it requires a temporary closure of a large portion of the Svanemøllen harbour. During the construction phase harbour facilities and about half of the boat floating docks will be moved to the nearby Færgehavn Nord harbour. The temporary marina called Erstatningshavnen (Replacement Harbour) includes the construction of floating docks for berthing approximately 600 boats, a new breakwater and a new crane area. The existing dockside walls consist of steel sheet piles with one anchor level constructed in the 1960’s and will be kept.

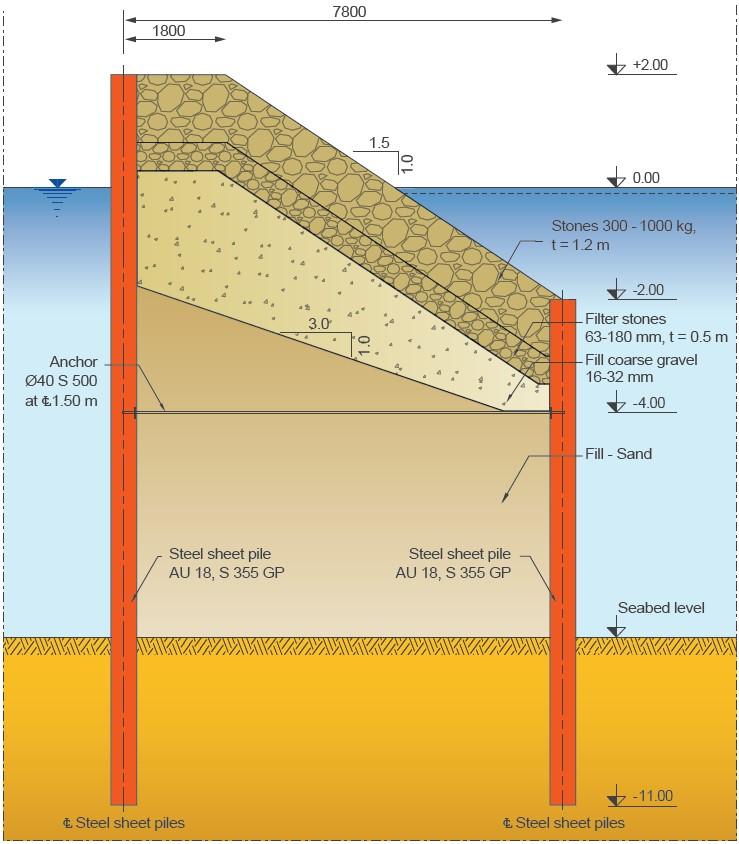

ArcelorMittal supplied 1 190 tonnes of AU 18 sheet piles, in steel grade S 355 GP, with a length ranging between 7.0 m and 13.0 m for the breakwater, and some 65 tonnes of 10.0 m – 10.7 m long GU 12N, S 355 GP, for a new dock at Svanemøllehavnen.

The budget of the entire project is 3.4 billon DKK and the tunnel should be ready for traffic in summer 2027, with an expected traffic of 8 200 vehicles per day.

The replacement harbour Færgehavn Nord has been carried out as a traditional design-bid-build contract, whereas the Nordhavn Tunnel will be carried out as a design & build contract.

The tender for the replacement harbour was issued in April 2021, and the construction company Munck was awarded the contract on September 2021 to build it for the amount of DKK 75 mio (approx. € 10 mio).

The curved breakwater has a combined length of 450 meters and has been designed and executed as a double wall cofferdam with the front sheet piles installed (on the sea side) with a top level at -2.0 m and the back sheet piling installed with a top level of +2.0 m. The steel sheet pile walls are anchored at the elevation -4.0 m with a tierod of diameter 40 mm in steel grade S 500 spaced 1.5 m apart. After the piles were installed, the space between the two sheet pile rows of the cofferdams was filled with sand and three different types of rock elements on top.

The sheet piles were driven with a high frequency vibratory hammer ICE 14RF with a variable moment of 14 kgm, a centrifugal force of 812 kN, an ICE 28RF with a variable moment of 28 kgm, a centrifugal force of 1 600 kN, and an impact hammer of 6 t mounted on a Junttan PM 20 telescopic rig. The short AU 18 sheet under water were driven with a Movax piling hammer DH-35 (ram weight of 3.1 t and an impact energy of 0 - 35 kNm) mounted on an Hitachi excavator.

A small dock for lifting the boats was built at the Svaneknoppen and is in operation since April 2022.

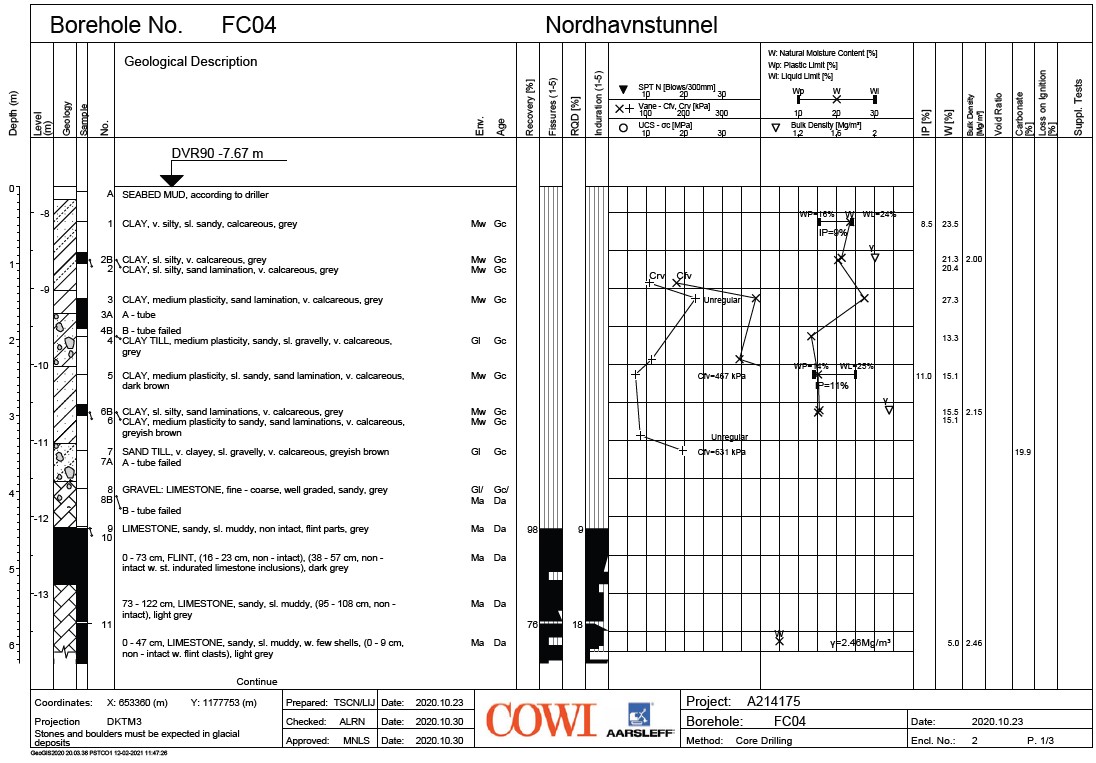

The double wall cofferdam is built at the entrance of the new marina. The existing seabed level varies from approx. -6.0 to -8.0 m. The upper layers in which the sheet piles were driven consist typically of fills, gyttja, clay, clay till, silt, sand, sand till, gravel, limestone, limestone till, etc.

The execution of the breakwater started in October 2021 and finished in July 2022 when the effective move of the boats started.