Guidelines. Sustainability of steel sheet piles

Environmental Product Declarations and Life Cycle Assessments

What is a Life Cycle Assessment?

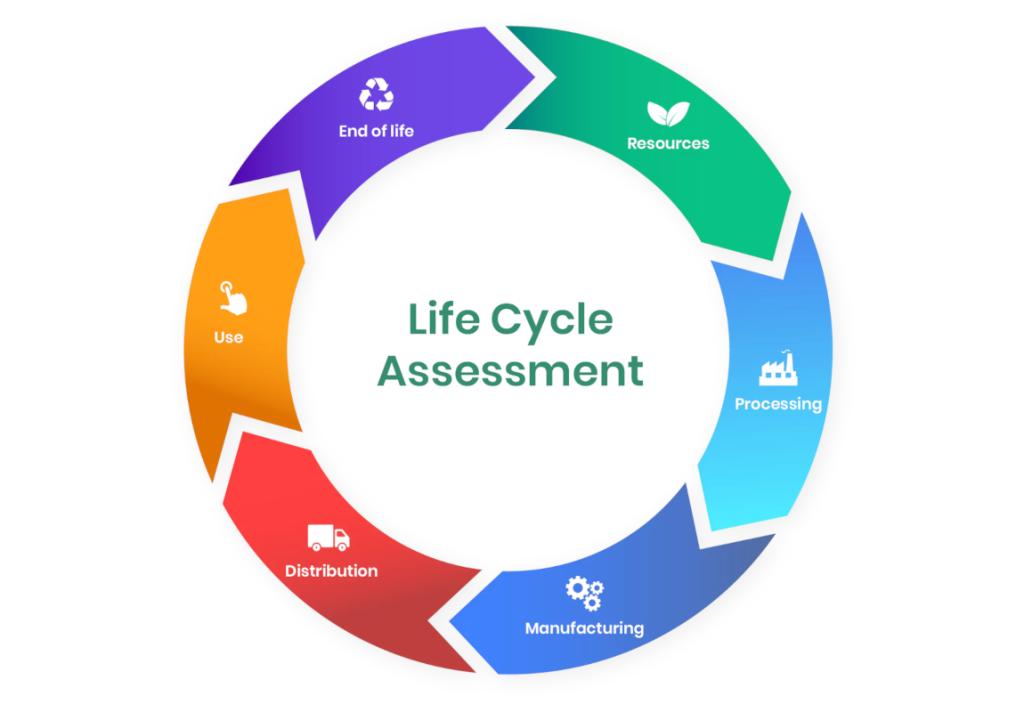

A Life Cycle Assessment (LCA) is a systematic analysis and evaluation of the environmental impacts of a product (or service) for its entire life cycle. The life cycle of a product in the construction industry includes the extraction of raw materials and their further processing, transport, manufacture, all further processing steps before installation at the construction site, the use phase, disassembly and finally the reuse or recycling of the product.

What is an Environmental Product Declaration?

An Environmental Product Declaration (EPD) is a document that describes the environmental impacts of a product based on a life cycle assessment with quantitative data. An EPD enables manufacturers to transparently communicate the environmental impacts of products. EPDs in turn form the basis for the ecological assessment of buildings and other construction projects.

ArcelorMittal’s EPDs are verified by independent experts and published at EPD International.

![Global Warming Potential [kg CO2e t sheet pile]](/sites/default/files/inline-images/Global%20Warming%20Potential%20kg%20CO2e%20%20t%20sheet%20pile.png)

Download

English

English

English (USA)

English (USA)

German

German

French

French