Water Transport Solutions

Maritime ports

Ship Lifts, Dubai Maritime City | 2008

Download the full case study

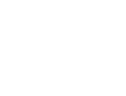

The design

With execution time being the crucial criterium, a sheet pile wall with AZ 50 was proposed as an alternative solution. Finally the main wall is made of AZ 50, whereas the anchor wall is made of AZ 18 sheet piles. For the local high vertical loads that will occur during the operation of the ship lift single AZ 50 box piles, called CAZ 50, were driven. This cost-efficient solution is the result of intense optimizing efforts carried by the technical department of BESIX in cooperation with the design department of ArcelorMittal Commercial Rails, Piles & Special Sections.

The installation

Being aware of the significant influence of freight rate for the building material on the total cost, the box piles were fabricated on site so that all sheet piling could be delivered stacked with a minimum of required space. The assembly of the CAZ 50 box piles was eased by delivering AZ 50 piles with already cut flanges.

A characteristic of the soil conditions in the Dubai area is the cap rock. At this location, cap rock is found at a depth of about -19.00 m thus leading to hard driving conditions. The installation was carried out with vibratory hammers (ICE 815C and ICE 1412) as well as a hydraulic impact hammer (IHC S90) without any further driving assistance. A two level template was used to guide the sheet piling during driving with free hanging driving equipment. The tolerances for the positioning of the box piles were very strict, as these piles represent the connection point between the mechanical part of the ship lift, the retaining wall and the transfer rail.

Due to the high vertical loads during the operation of the ship lift, the box piles have to provide a high bearing capacity. The analysis of the driving records from the installation did allow a first estimation of the bearing capacity. These values span from 3.2MN to 6.5MN.

To prove the bearing capacity of the CAZ 50 box piles, statical vertical load test was carried out which confirmed the foundations calculated values and finally did verify the values estimated during the design calculations.

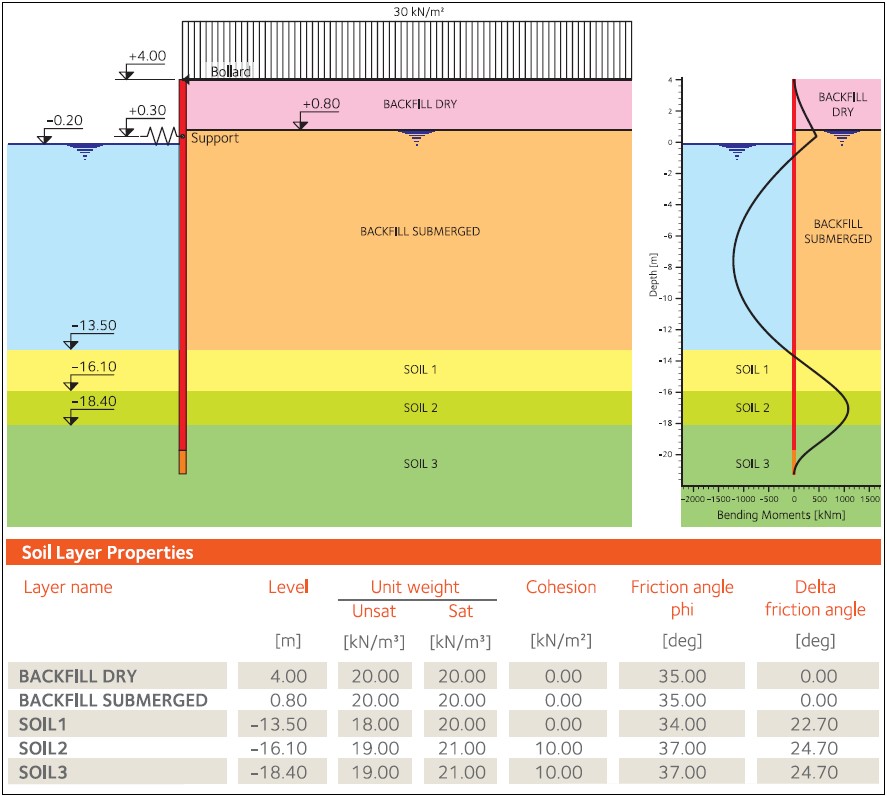

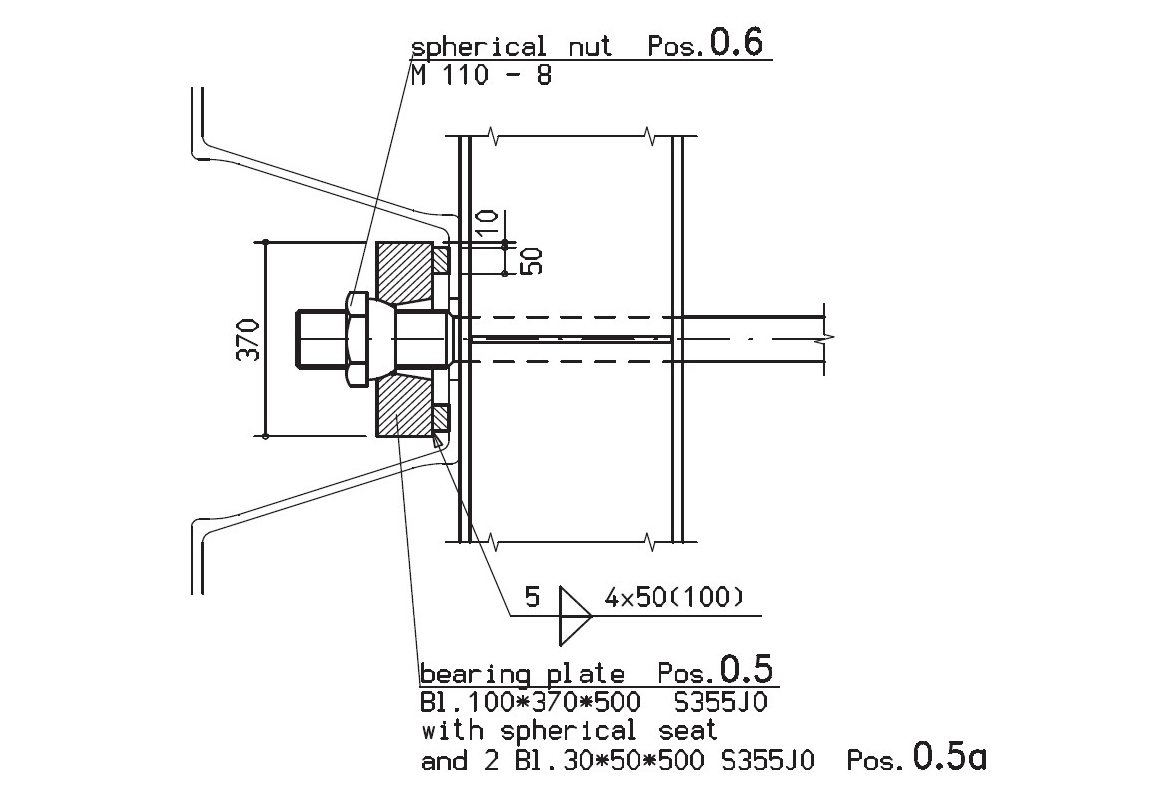

Anchor material

As an integrated part of the design of the structure the specific anchoring layout was developed as a tailor made pre- fabricated system of tie rods and waling which was provided by Anker Schroeder, Germany. All required materials such as tie rods, waling, bolts, nuts and plates were delivered to the site and simply had to be assembled with a minimum of work to be carried out on the field. Even the connections of the waling beams were already prepared with drilled holes. Bearing in mind that the site is located on a reclaimed area right on the shoreline and the anchor level of the sheet piling is lower than the high tide level, the waling and the tie rods could only be installed at low tide under dewatering conditions. Therefore the choice of prefabricated anchor material was the only way to carry out these works in a cost–effective way.

Conclusion

The installation of the sheet piling for the ship lifts in Dubai Maritime City was completed within the time frame as initially planned. The excellent preparation of this project from the design phase to the execution of the structure took advantage of a high degree of prefabrication and lead to a successful completion.