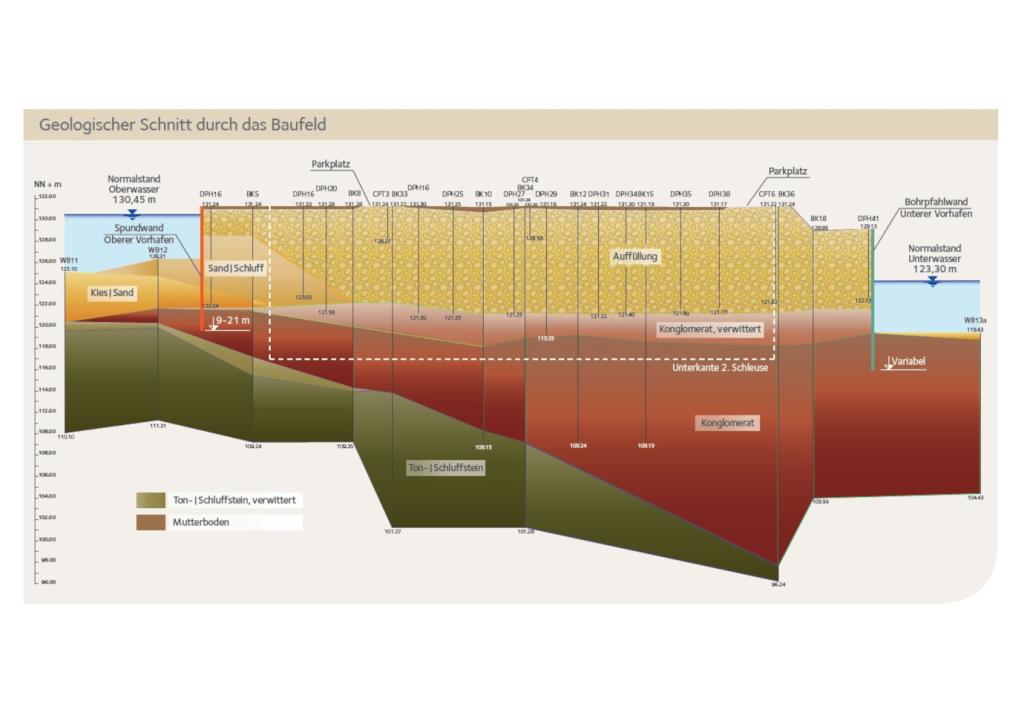

River locks in Trier, DE | 2018

Upgrading Moselle Locks with Second Chamber

Since the completion of the first construction phase in 1964, the Moselle has been used as a major European waterway. After further expansion stages, it can be navigated by ships and barges up to 135 m and 172 m in length respectively, with a width of 11.45 m, from the French town of Neuves-Maison to Koblenz, as a Class V-b waterway.

However, the existing locks are no longer up-to-date in their dimensions and cause waiting times for lock passages. In addition, the transportation of goods shares the route with abundant tourist excursion boats. Therefore, the locks are now being gradually equipped with a second lock chamber, with standard dimensions of 210 m x 12.5 m.

Download

German

German