Water Transport Solutions

Maritime ports

3,295 tonnes of sheet piles

Rehabilitation of Port of Durban, ZA | 2012

Download the full case study

The port has 57 berths and is protected by the north and south breakwaters, which are 335 m and 700 m long respectively. It was developed primarily for import cargo but over the years, cargo flows have changed significantly and exports have become more important.

Over 4 000 commercial vessels call at the port each year.

The Maydon Wharf Multi-Purpose Terminal (MPT) handles a variety of containerised, break-bulk and bulk cargo, and specializes in the handling of specific commodities. Additionally the terminal also handles both import and export containers, handling on average 15 000 TEU’s. The terminal has an annual throughput of more than 1 million tons of break-bulk and neo-bulk commodities. The Maydon Wharf area consists of 15 berths, the MPT operates principally between Berth 8 and 13.

Transnet National Ports Authority (TNPA) has initiated a massive upgrading of the infrastructure at the port. One of the major projects is to rebuild and deepen 7 of the 15 berths at the Maydon Wharf area. The new quays are to accommodate larger vessels and to provide suitable load carrying capacity for the handling of cargos over the berths.

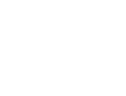

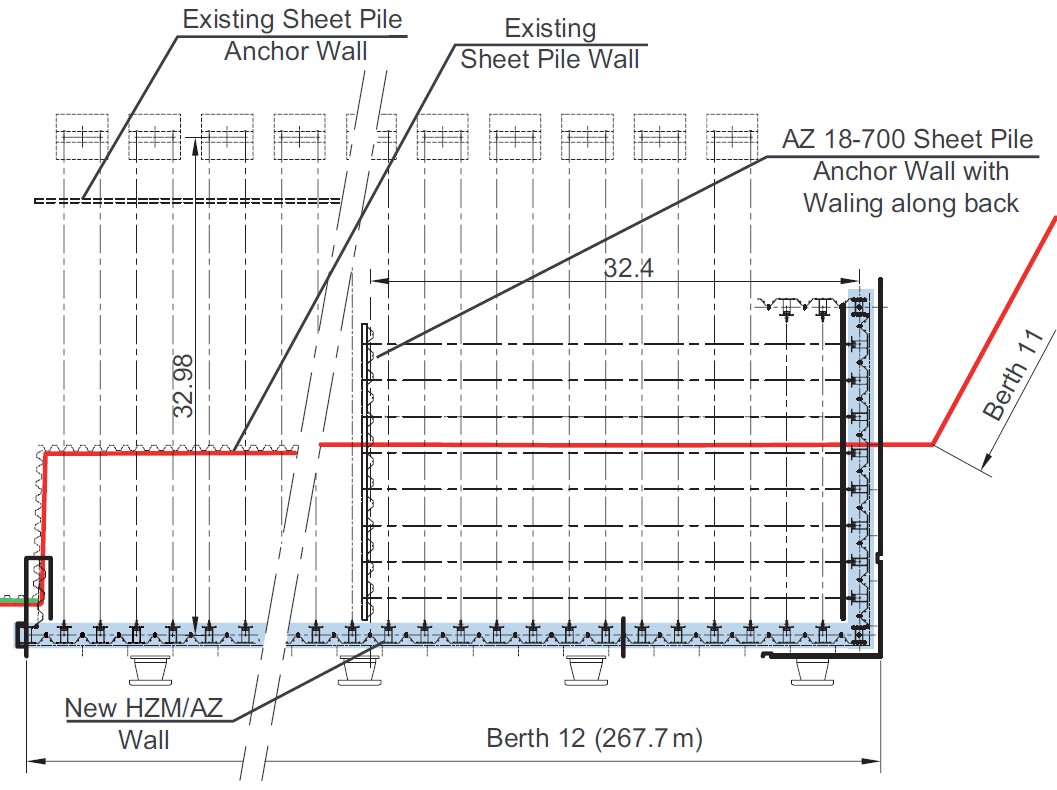

The berths will be deepened from -10 m CD to -14.5 m CD in the future. Berth 12 is the first reconstruction project that was launched. The quay wall is approximately 270 m long, with a return wall of 33 m along Berth 11. The new front line of the wall lies 13 m in front of the sheet pile wall of the existing berth.

The quay wall has been built with the new HZM/AZ combined wall system: over 2 800 tonnes of HZ 1180M A-24 king piles and 440 tonnes of AZ 18-700 sheet pile pairs as intermediary piles. A high strength steel grade S 430 GP (430 MPa yield strength) has been chosen by the design engineer in order to optimize the steel quantities needed. The combi-wall system is anchored with tie-rods to a reinforced concrete anchor wall. The new quay wall and capping beam were designed to put up a future front rail for a container gantry crane.

The HZM king piles are 27.3 m long, with a weight of 22.8 tonnes each. They were driven to depth with a free hanging vibratory hammer with variable frequency, suspended on an hydraulic crawler crane Kobelco CKE 1800 and an impact hammer. A special two level template has been used for the installation of the combi-wall. The HZM piles are driven in a first phase down to grade, guided in the correct position inside the template, then the infill sheets are installed. This standard installation procedure ensures the verticality and correct position of the two components. The AZ infill sheets are shorter than the HZM, as their main function is to distribute the horizontal loads to the HZM king piles.

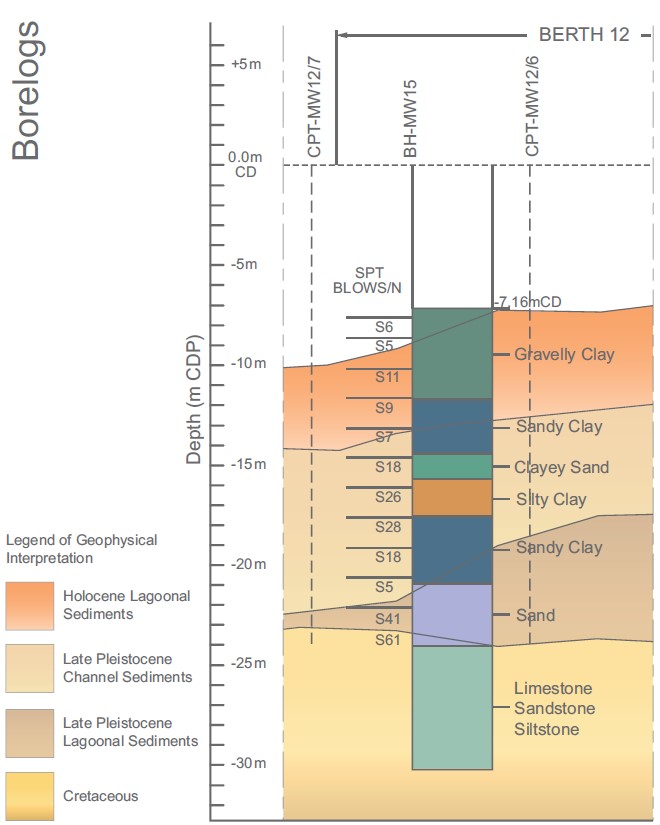

The soil is quite heterogeneous, ranging from soft sandy clays to very compact sands with SPT values above 90. Part of the HZM king piles were driven into the siltstone / sandstone layer (top of the cretaceous horizon between -23 m and -30 m CD).

Despite the hard soil conditions, the 123 HZM/AZ elements were installed in due time.

The service life of the structure is 50 years. To protect the immersion zone, the design engineer opted for a cathodic protection with sacrificial anodes. They will be installed under water on plates that are welded to the AZ sheet piles prior to driving. The concrete capping beam reaches below ‘Low Water Level’ and protects the steel above this level (intertidal and splash zone).

ArcelorMittal also supplied the tie-rods as part of the whole foundation solutions package. These are fixed with a specific T-connector to the HZM king pile, the advantage being that the installation is very simple as they do not require any welding at the job-site. The threads of the tie-rods are M 115, with a 90 mm diameter shaft, 500 mm long upset threads on one end, and eye tie-rods on the other end. The yield strength of the tie-rods is 500 MPa.

Commissioning of this quay wall is foreseen by end of 2012.