Water Transport Solutions

New lock

New Lock of Ivoz-Ramet Flémalle, BE | 2011

In the last 20 years, the traffic at this location has grown from 6 million to 12 million tonnes per year. As a result, the existing 136 m x 16 m lock (class Va, CEMT classification) is now near to saturation. To allow the traffic of class VIb vessels up to 9000 tons, and to reduce waiting times, the Service Public de Wallonie (SPW) has, therefore, decided to build a new and larger lock, sized 225 m x 25 m, with a maximum water head difference of 4.45 m.

Download the full case study

The space available for this new lock was constrained by a road and railway on the right river bank, a hydro power station and a weir, serving as road bridge, on the left bank, and important urban and economical developments in the surroundings. The only possible location for the new structure was between the existing 136 m x 16 m lock and the weir, dismantling the old 55 m × 7.5 m lock.

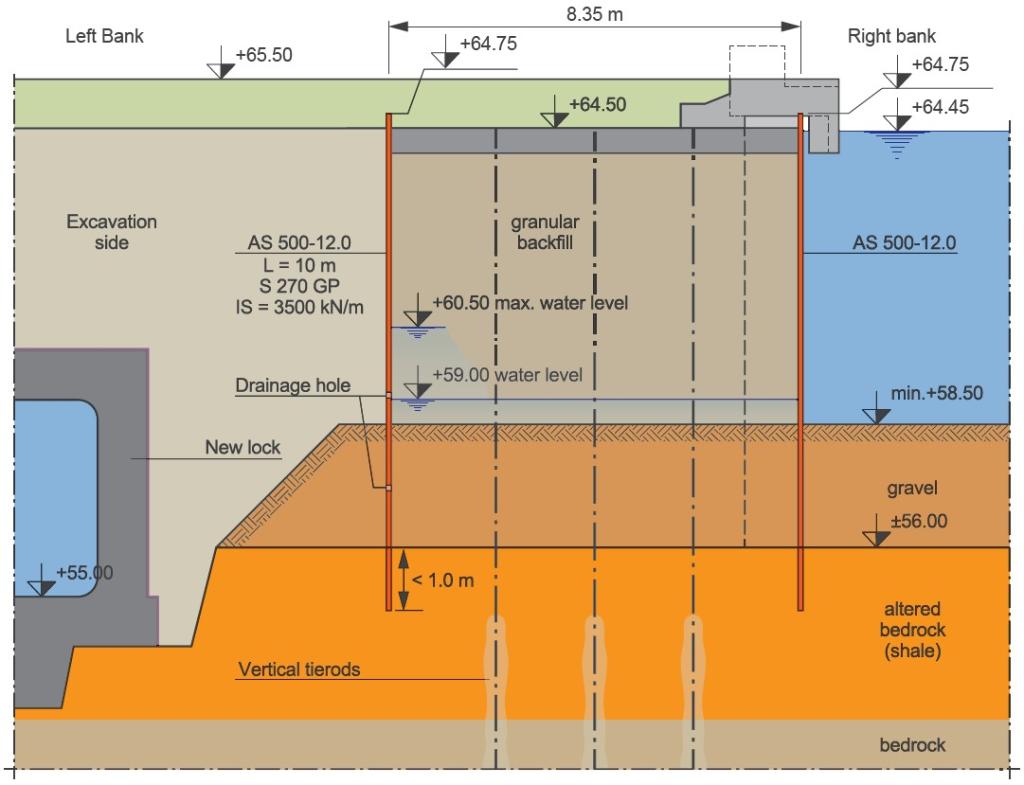

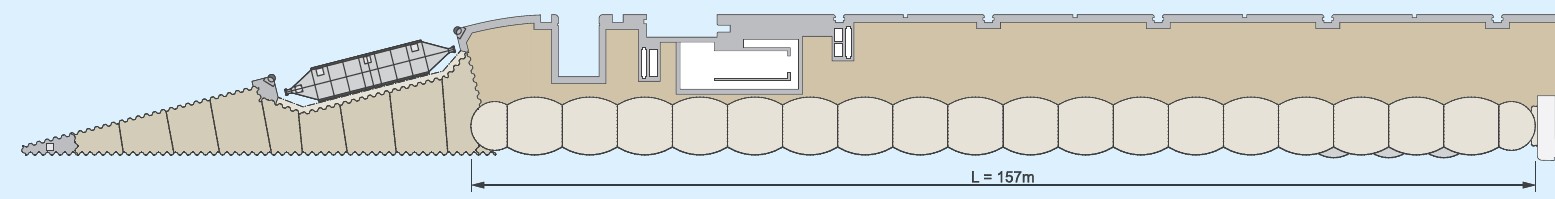

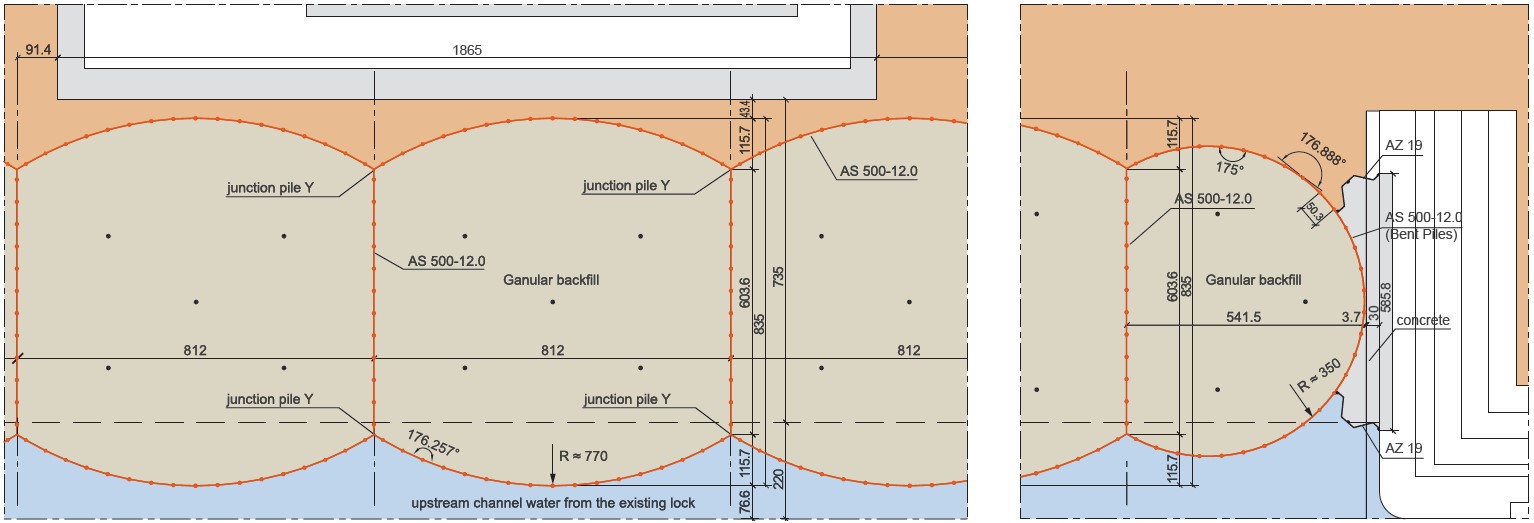

Because the existing lock had to be maintained in service during the works, no extra space was available for temporary retaining walls on the side of this lock. The designers solved this problem with a cofferdam wall of 20 diaphragm cells with 10 m long AS 500 straight web sheet piles. The gravity wal is autostable and serves as a permanent retaining wall for the island between the current and the new lock. Three arc cells were added on the side of the cofferdar wall and filled with concrete to serve as abutment for a 32 m long swivel bridge that connects the island with the right river bank.

Additionally, 15.000 m2 of temporary sheet piles were used as retaining walls for the construction of the new lock.

The AS 500 flat steel sheet piles were driven through the bottom of the river (alluvium, mainly sand & gravel) up to 1 m into the bedrock (altered shale) with a PTC 34 vibrator. Two single level driving templates, resting on temporary steel tubular piles, were used to install the sheet piles: one for the 18 diaphragm cells and one for the two circular closing cells.

The 20 cells of the diaphragm wall were backfilled with granular soils, covered by a concrete slab in which vertical tie rods were installed to anchor the cells to the bedrock. The tension of these prestressed tie rods was monitored and could be adjusted according to the stages and the consolidation grade of the backfill. Due to the high tensile forces in the interlocks of straight web sheet piles, the diaphragm cells are permanently watertight.

Draining holes on the excavation side of the cells allowed drainage of the fill.

The water table inside the cells was monitored with vertical tubes that went down to the tip of the cells. If necessary, pumps could be lowered in these tubes to improve the drainage of the fill. The deformation of the cells was also closely monitored during the works.

Downstream the lock complex, steel tubes Ø1067x11 mm were used as foundation piles for the exit guiding walls and Ø1067x14 mm for dolphins. The dolphin tubes were installed into holes Ø1500 mm, bored into the bedrock through temporary steel casings. To anchor the tubes, their base was filled with concrete, which could flow into the holes via openings in the tube’s base.

The works started in May 2011 and will be completed in 2015.