Mobility Infrastucture Solutions

Half-time at the Saale-Elster viaduct, DE | 2006

Once completed, it will secure traffic flows from Nuremberg to Berlin and from Frankfurt/M. to Dresden.

Download the full case study

The main bridge crosses the Saale-Elster floodplain in an east-west direction over a length of 6,456 m, with a 2,112 m branch to the north towards Halle in the middle of the structure.

According to the framework plans of DB AG, the supporting structure consists of single-cell box girders made of prestressed concrete; the superstructure systems are predominantly single-span girders with 44-meter pier spacing. Spans of up to 70 meters are only required in areas with switches and track widenings, or 110 meters for the overpass structure (branch to Halle).

Due to the location of the structure in the Saale-Elster floodplain, a nationally important floodplain landscape with a wide variety of species, numerous measures were taken to minimize disruption to the landscape and biotope:

- Reorganization of the drinking water protection zones so that the structure is located outside Zones I and II

- Sealing of the construction routes in Zone III

- Construction of closed rainwater retention basins with light liquid separators and buoyancy protection for safety in the event of overflowing of the floodplain

- Pre-head construction of the bridge structure in areas of particularly high ecological value.

Ecological aspects were also taken into account in the foundation of the 242 piers that support the bridge structure:

- All piers are founded flat within sheet pile boxes fitted with interlock seals.

- The sheet pile walls structurally tie into the reservoir layers of the adjacent variegated sandstone and tertiary sediments

- and thus ensure the separation of the structure from the groundwater.

They remain in the ground and are permanently protected against corrosion by an internal coating. There is a force-fit connection between the foundation and the sheet pile wall. This ensures load transfer via the sheet pile box and reduces settlement.

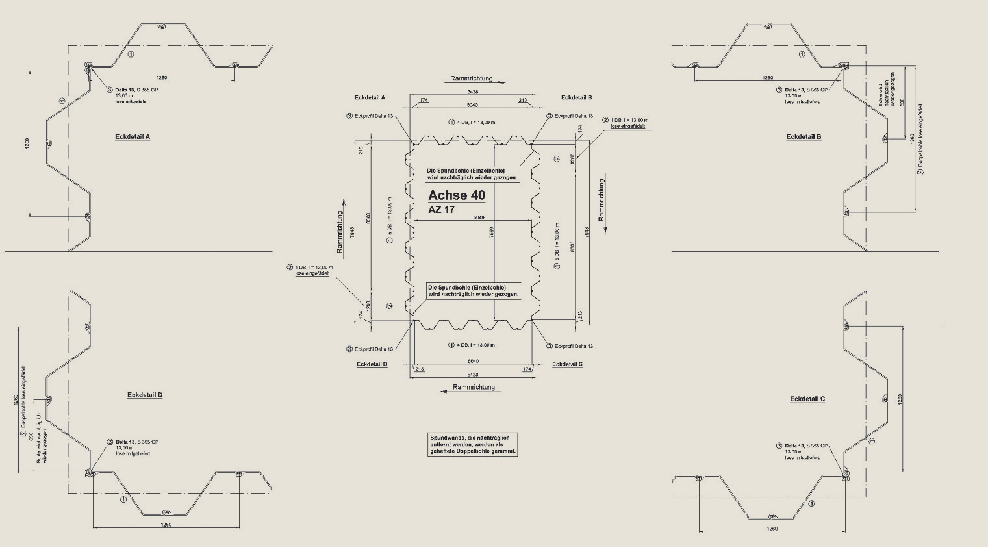

For technical and design reasons, as well as for reasons of corrosion protection (same wall thickness of the profiles all round), Z-profiles of the AZ 18 and AZ 26 profile groups were used for the foundations of the piers.

By June 2009, the following had been installed for

- 147 piers

- 2 rainwater retention basins and

- one sealing wall

- a total of 9,375 tons of sheet piling had been delivered. For 2009 to 2011, further

deliveries of around 6,000 tons are planned.