Steel grades

Hot rolled and cold formed sheet pile sections

Steel grades of hot rolled sheet pile sections

The whole range of ArcelorMittal’s hot rolled steel sheet piles can be delivered in steel grades according to the European standard EN 10248 – Part 1:2023, but note that not all profiles are available in all steel grades. Standardized yield strength fy (Note: the value of ReH is used in the European standard) start at 240 MPa and go up to 500 MPa. The new version of EN10248-1:2023 introduces new requirements on the steels: CEV values (carbon equivalent value) and impact properties (Charpy V-Notch test).

The tables below summarize the current availability.

Steel grades of cold formed sheet piles are detailed at the bottom of the page.

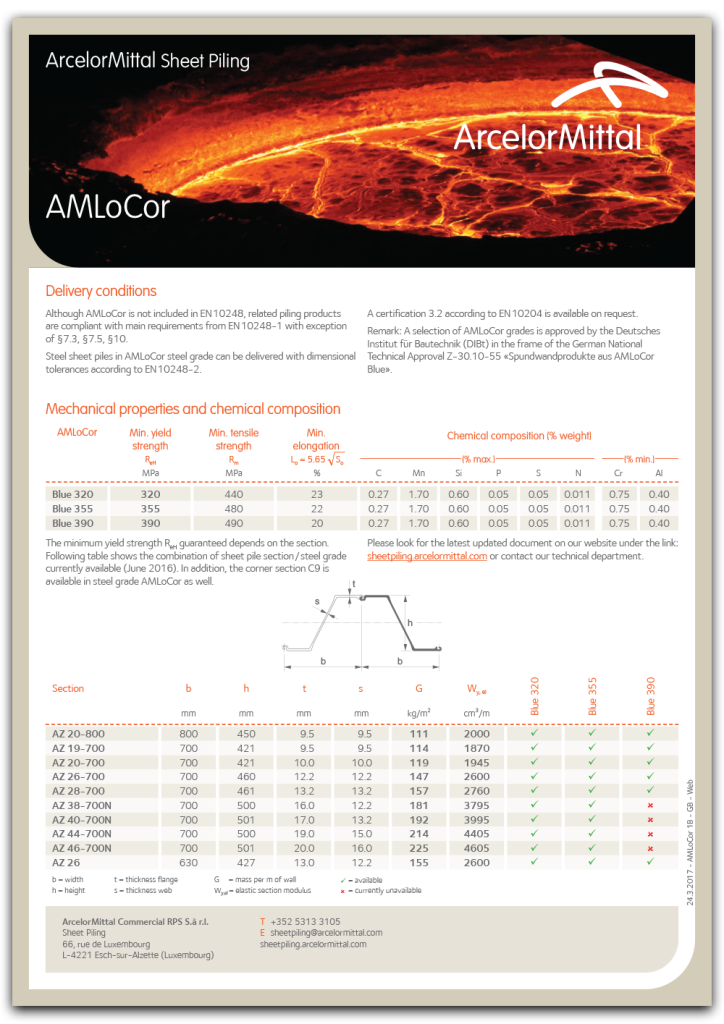

Special steel grades such as American ASTM A572 steel grades, steels with improved corrosion resistance, such as AMLoCor® and ASTM A690, or steels with copper addition in accordance with EN 10248 – Part 1:2023, Chapter 7.2.4, can be supplied on request. A modified steel grade A690 with a higher yield strength is also available for some sheet pile sections.

We strongly recommend to our customers informing us of any surface treatment that will be applied to the product before placing orders. For instance, hot-dip galvanization can only be applied correctly to steel with a specific chemical composition (see EN 10248 – Part 1:2023, Chapter 7.4.3). Therefore, customers must mention in their enquiry that the sheet piles will be galvanized, and confirm it in the purchase order.

Steel grade availability may change at any time, without prior notice, so please contact us for updated information.

| Minimum yield strength | Minimum tensile strength | Minimum elongation | Minimum impact energy KV2 | Minimum yield point | Minimum tensile strength | Minimum elongation | |||

|---|---|---|---|---|---|---|---|---|---|

| Standard or Specification | Steel name (Steel grade) | ReH | Rm | A1) at fracture | Testing temperature | J | fy | fu | L2) |

| MPa | MPa | % | °C | Joules | ksi | ksi | % | ||

| EN 10248 | S 240 GP | 240 | 340 | 26 | 20 | 27 | 34.8 | ||

| S 270 GP | 270 | 410 | 24 | 20 | 27 | 39.1 | |||

| S 320 GP | 320 | 440 | 23 | 20 | 27 | 46.4 | |||

| S 355 GP | 355 | 480 | 22 | 0 | 27 | 51.5 | |||

| S 390 GP | 390 | 490 | 20 | 0 | 27 | 56.5 | |||

| S 430 GP | 430 | 510 | 19 | 0 | 27 | 62.3 | |||

| S 460 GP | 460 | 530 | 17 | 0 | 27 | 66.7 | |||

| S 500 GP | 500 | 580 | 15 | 0 | 27 | 72.6 | |||

| AMLoCor® | Blue 320 | 320 | 440 | 23 | 46.4 | ||||

| Blue 355 | 355 | 480 | 22 | 51.5 | |||||

| Blue 390 | 390 | 490 | 20 | 56.5 | |||||

| ASTM A572 | Gr. 50 | 345 | 450 | 50 | 65 | 18 | |||

| Gr. 55 | 380 | 485 | 55 | 70 | 17 | ||||

| Gr. 60 | 415 | 520 | 60 | 75 | 16 | ||||

| Gr. 65 | 450 | 550 | 65 | 80 | 15 | ||||

| ASTM A690 | Gr. 50 | 345 | 485 | 50 | 70 | 18 | |||

1) Minimum elongation on a gauge length of L0 = 5.65 SQRT(S0)

2) Minimum elongation with a test sample of 8 in. [200 mm]. See ASTM A6/A6M

fy: min. yield point (ASTM)

fu: min. tensile strength (ASTM)

| Standard or Specification | Steel name (Steel grade) | Chemical composition in % by mass | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| max. | min. | ||||||||||

| C | Mn | Si | P | S | N | Cu | CEV | Cr | AL | ||

| EN 10248 | S 240 GP | 0.19 | 1.50 | - | 0.050 | 0.050 | 0.014 | 0.60 | 0.38 | - | - |

| S 270 GP | 0.20 | 1.60 | - | 0.050 | 0.050 | 0.014 | 0.60 | 0.43 | - | - | |

| S 320 GP | 0.22 | 1.70 | 0.60 | 0.045 | 0.045 | 0.014 | 0.60 | 0.50 | - | - | |

| S 355 GP | 0.22 | 1.70 | 0.60 | 0.045 | 0.045 | 0.014 | 0.60 | 0.50 | - | - | |

| S 390 GP | 0.22 | 1.80 | 0.60 | 0.045 | 0.045 | 0.014 | 0.60 | 0.52 | - | - | |

| S 430 GP | 0.22 | 1.80 | 0.60 | 0.045 | 0.045 | 0.014 | 0.60 | 0.52 | - | - | |

| S 460 GP | 0.22 | 1.80 | 0.60 | 0.045 | 0.045 | 0.014 | 0.60 | 0.52 | - | - | |

| S 500 GP | 0.22 | 1.80 | 0.60 | 0.045 | 0.045 | 0.014 | 0.60 | 0.52 | - | - | |

| AMLoCor® | Blue 320 | 0.27 | 1.70 | 0.60 | 0.050 | 0.050 | 0.011 | - | - | 0.75 | 0.40 |

| Blue 355 | 0.27 | 1.70 | 0.60 | 0.050 | 0.050 | 0.011 | - | - | 0.75 | 0.40 | |

| Blue 390 | 0.27 | 1.70 | 0.60 | 0.050 | 0.050 | 0.011 | - | - | 0.75 | 0.40 | |

Please refer to the European standard EN 10248-1:2023 and ASTM standards for additional details on applicability of the values in above tables.

CEV = Carbon Equivalent Value.

Steel grades - cold formed steel sheet piles

PAZ, PAU and PAL cold formed steel sheet piles, as well as trench sheets RC are available in steel grades according to EN 10249 – Part 1, with a yield strength fy starting at 235 MPa and up to 355 MPa.

Check our brochure for the availability of the different combinations steel grade / sheet pile section.

| Standard / specification | Steel grade | ReH | Rm | Lo1) |

| MPa | MPa | % | ||

| EN 10249 - Part 1 | S 235 JRC | 235 | 360 - 510 | 26 |

| S 275 JRC | 275 | 410 - 560 | 23 | |

| S 355 J0C | 355 | 470 - 630 | 22 |

ReH: min. yield point

Rm: min. tensile strength

1) Minimum elongation measured on a sample with L0 = 5.65 * SQRT(S0)