Anchorage - Tie-rods

Anchors For Marine Structures M64 – M170 in accordance with EN1993-5

Anker Schroeder anchors for marine structures

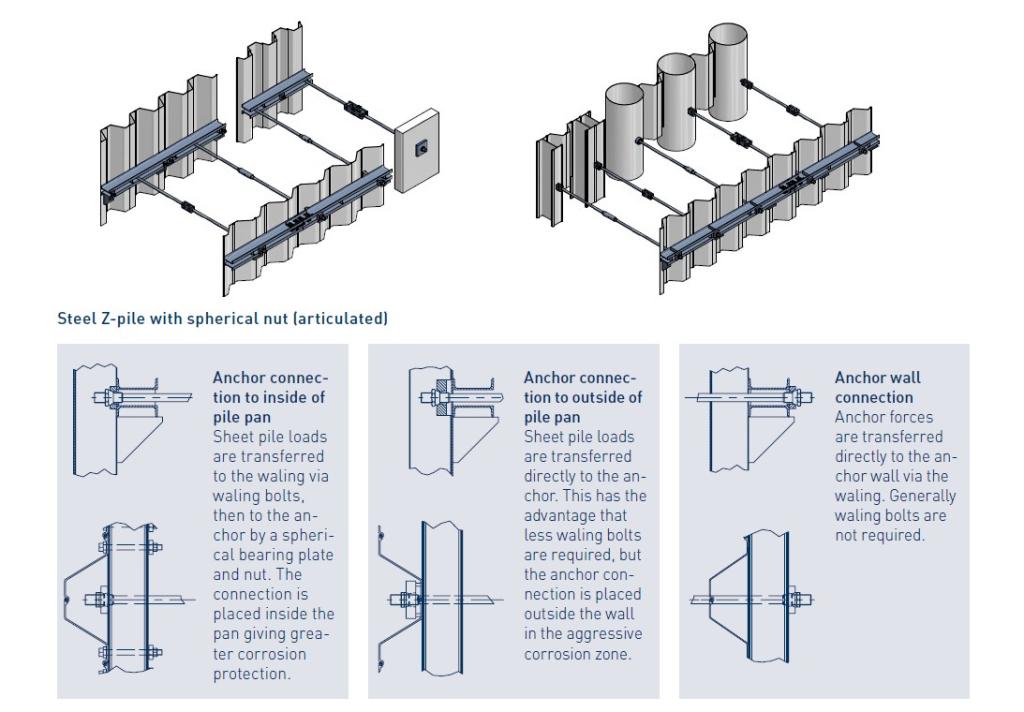

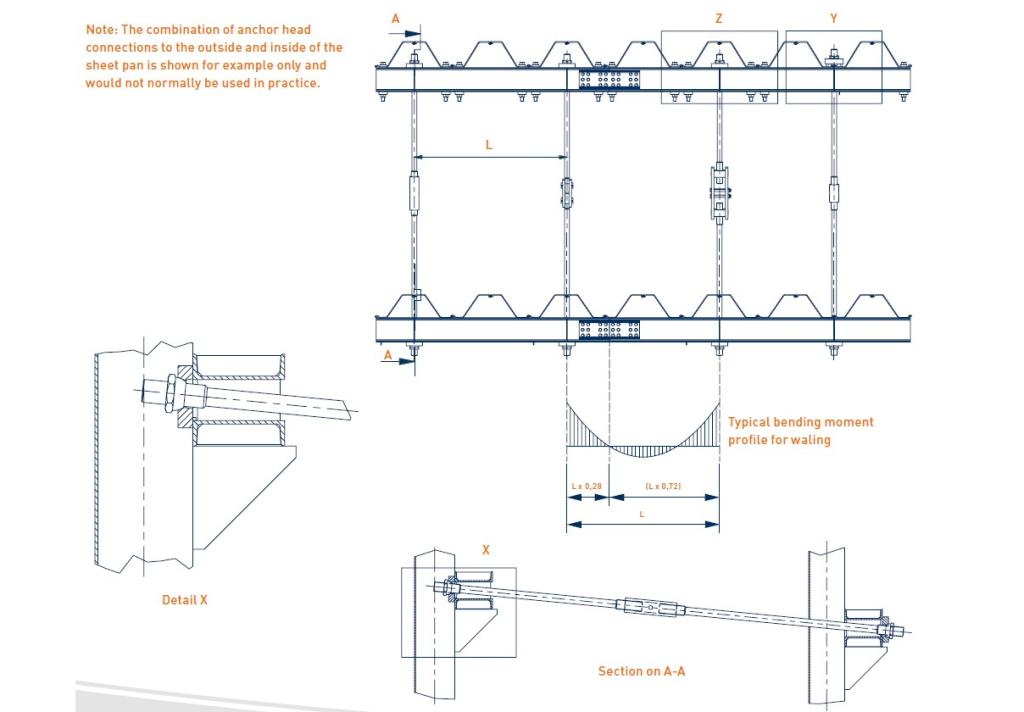

Anker Schroeder manufacture anchors for retaining structures such as quay walls, abutments, berths and crane runways. Our anchors range in diameter from M64 to M170 and can be supplied in grades 355, 460, 500 & 700. Anker Schroeder anchors are manufactured from round steel bar with forged or threaded ends that allow a variety of connections to be made to sheet piles, tubes, H-piles, combi-walls and diaphragm walls.

Depending on diameter and length required Anker Schroeder tie bars are manufactured using selected fine grained steel, high strength low alloy steel or quench and tempered steel. The choice of steel is dependent upon your specific project requirements but the above minimum properties will be met. All tie bars and components are manufactured to a quality system audited and accredited to ISO 9001 and meet the requirements of EN1090 and are CE marked (a legal requirement for supply into the European market).

Download

English

English

English (USA)

English (USA)

German

German

French

French

Spanish

Spanish