General Catalogue

Steel Foundation Solutions l New standard EN 10248-1:2023

General catalogue - steel foundation solutions

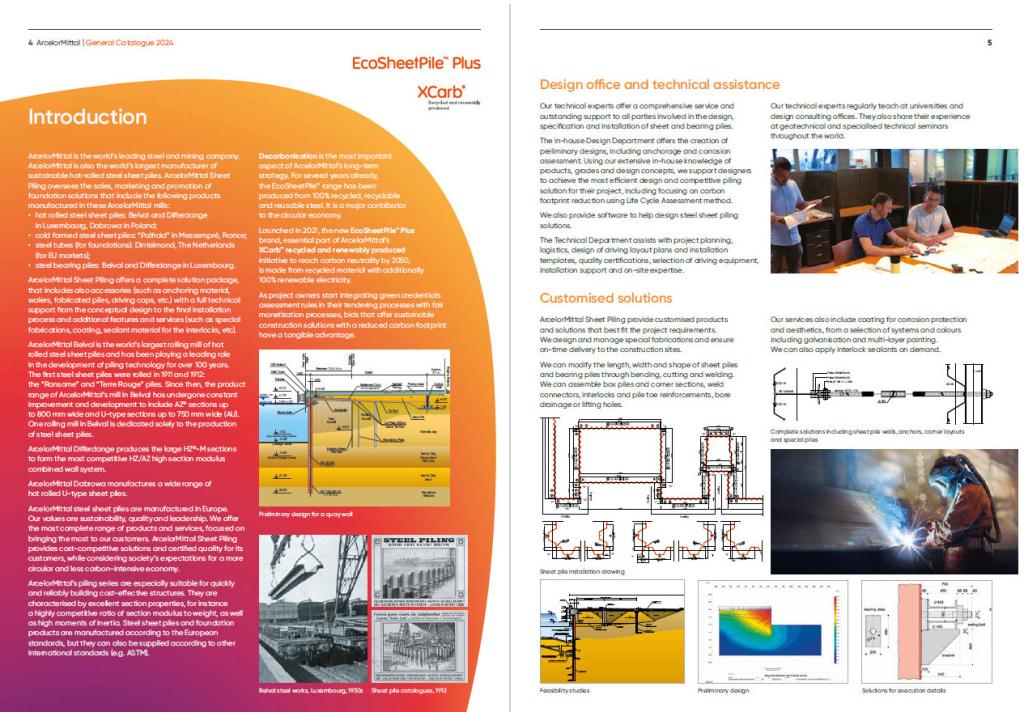

This document contains all technical data about steel sheet piles and other piling products (bearing piles, steel tubes), as well as accessories,... It contains also basic information about durability, coatings, sealing systems, delivery conditions, environmental impact,...

ArcelorMittal Sheet Piling is the worldwide leader in steel sheet piling technology, providing the most innovative foundation solutions. Our products are used worldwide for the construction of quay walls, waterways, flood protection barriers, mobility infrastructure projects and containment structures.

We offer complete package solutions, based on our wide range of products and services, expert technical support from the early design stages of a project to its completion, customized fabrication, just-in-time delivery and after-sales services. Our innovative solutions and technical support allow the design of optimized, sustainable and efficient steel sheet piling solutions.

Part of ArcelorMittal’s XCarb® recycled and renewably produced initiative, the EcoSheetPile™ Plus brand offers steel sheet piles manufactured from 100 % recycled scrap metal and with 100 % renewable electricity, allowing lower CO2e emissions than with the usual energy mix. Certified by a specific Environmental Product Declaration (EPD), the production of the EcoSheetPiles™ Plus range emits as low as 409 kg CO2e per tonne of steel produced.

The SmartSheetPile solutions provide an automatised monitoring system of the structure, helping to minimise downtime, optimise maintenance and extend the lifetime.

Download

English

English

English (USA)

English (USA)

German

German

French

French

Italian

Italian

Spanish

Spanish

Portuguese

Portuguese