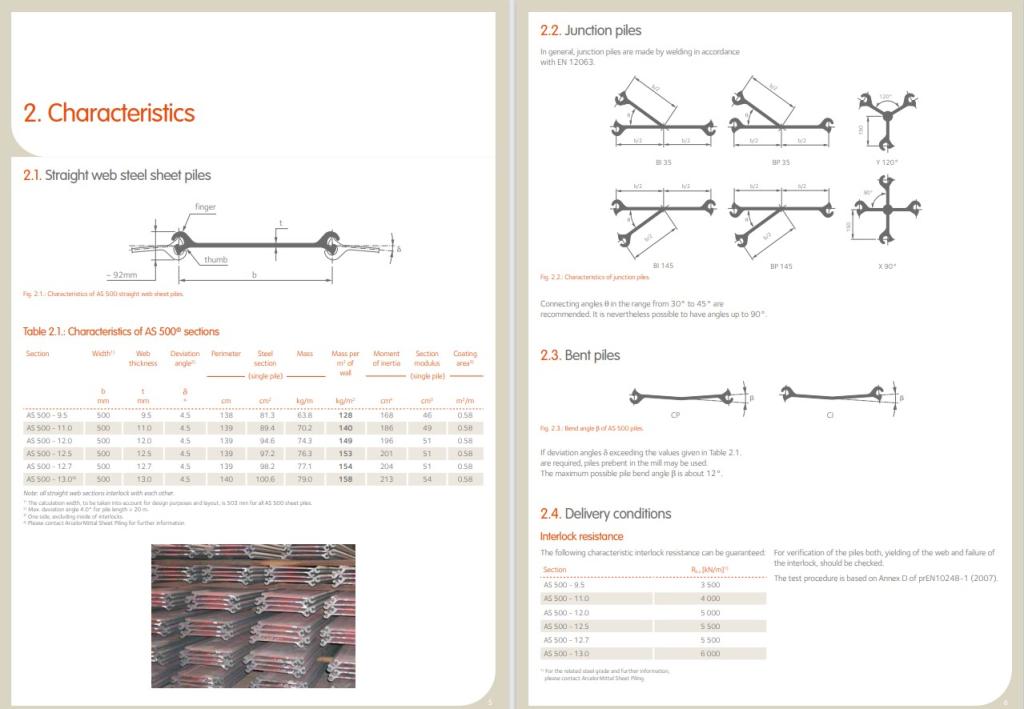

AS 500® Straight web steel sheet piles

Design & Execution Manual. AS 500® straight web steel sheet piles

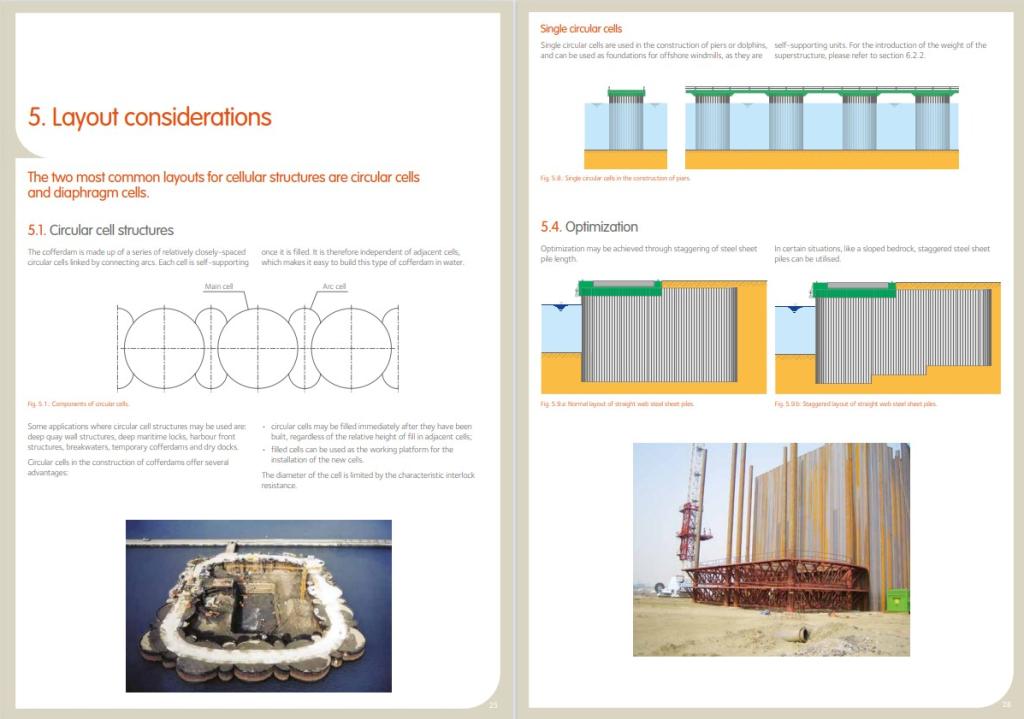

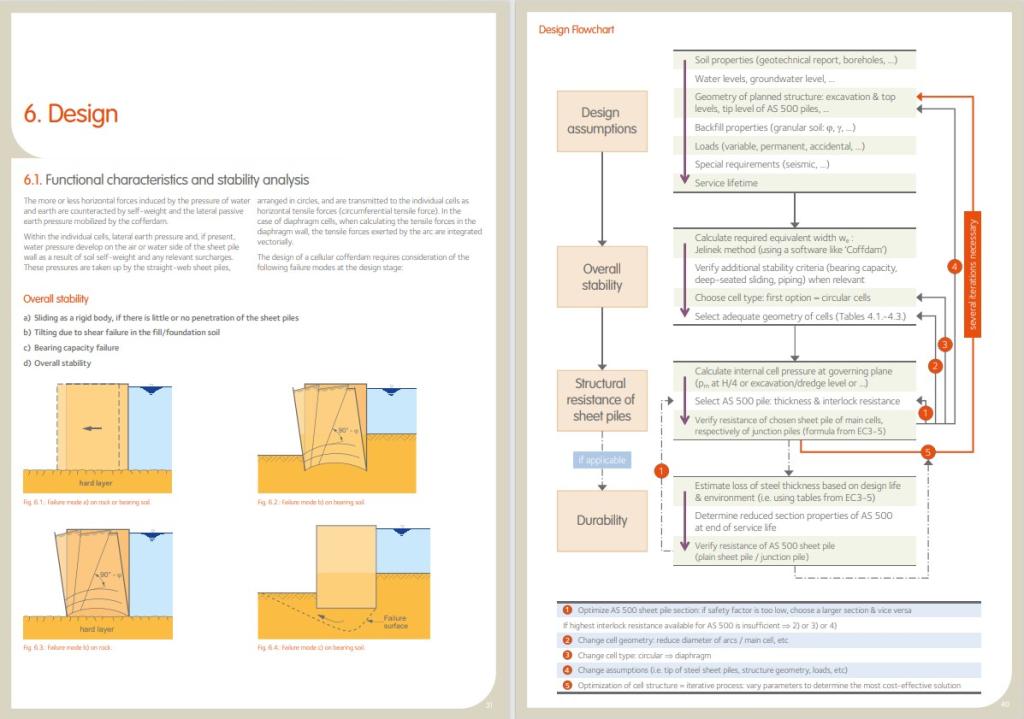

Cellular cofferdams can be designed as self-supporting gravity walls not requiring any supplementary waling and anchoring. They can be founded directly on bedrock, without any embedment. They are economical solutions for works in deep waters, high retaining works, and long structures.

The Applications of Straight Web Steel Sheet Piles fall into two categories: for temporary works and for permanent works:

1. Temporary Works:

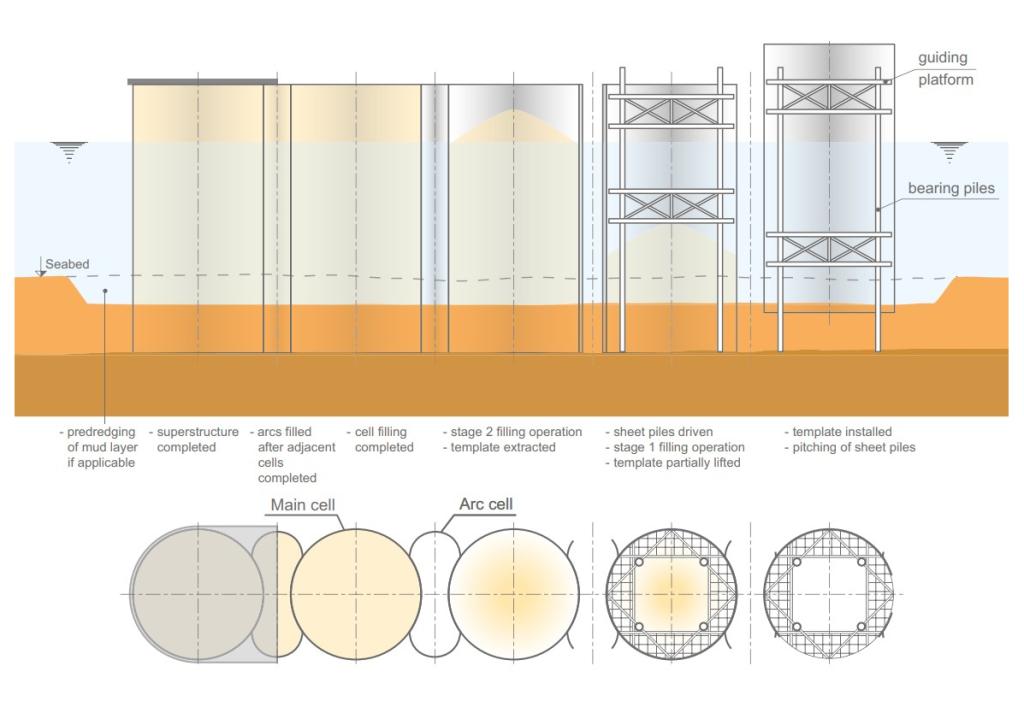

- Massive Cellular Cofferdams: Formed by a series of individual sheet pile cells, these cofferdams enable large and deep excavations to be carried out in dry areas or alongside riverbeds, often reaching down to bedrock.

2. Permanent Works:

- Quay Walls: These serve as both retaining walls and berths for ships, commonly used in the maritime-engineering sector.

- Piers and Jetties: Structures used for berthing ships on both sides.

- Dolphins: Single-cell structures used for berthing or guiding ships.

- Breakwaters: Structures designed to protect harbours, although berthing is typically not possible.

Related documents:

Download

English

English