AMLoCor®

Significantly increases the design life of marine structures

Introduction

ArcelorMittal’s ‘low corrosion’ steel grade will undoubtedly revolutionize the design of maritime infrastructure. As a matter of fact, steel sheet piles have been used for over 100 years to build reliable and cost-effective temporary and permanent structures worldwide. Countless quay walls of major European ports have been constructed with steel sheet piles. One concern of the designers and port authorities was the durability of these marine structures.

Corrosion of steel is a natural phenomenon that occurs whenever steel is in contact with humidity or water. However, it has not prevented investors and engineers from using steel in marine applications.

Several methods can be selected to achieve the predefined service life of a steel structure. One way to deal with the corrosion is to consider a certain loss of steel thickness over the service life, sometimes referred to as ‘sacrificial thickness’ or ‘static reserve’, and to take it into account in the design by considering reduced section properties of the sheet piles. Quite efficient but generally more expensive solutions are coatings and cathodic protection.

AMLoCor®

A more durable and long-lasting solution for building marine structures with AMLoCor, ArcelorMittal's low-corrosion steel grad

Durability is a challenge, that European manufacturers tackled over 20 years ago. First of all, by surveying many ports by official administrations, and publishing the results of corrosion rates. For instance, in Eurocode 3-Part 5, tables with typical corrosion rates can be found, valid for standard carbon steel in European countries.

But the foremost action was to start investigating into new steel grades that would be less prone to corrosion.

The key challenge was to develop a micro-alloyed steel that would perform better in the different zones to which a typical maritime quay wall is exposed. Several steel grades were tested in various ports over long periods. Many laboratory tests were conducted, to determine the influence of a range of parameters. Furthermore, trials at steel plants and rolling mills were done, to optimize the production of such special steels. The result has been the development of the ‘low corrosion‘ steel grade AMLoCor.

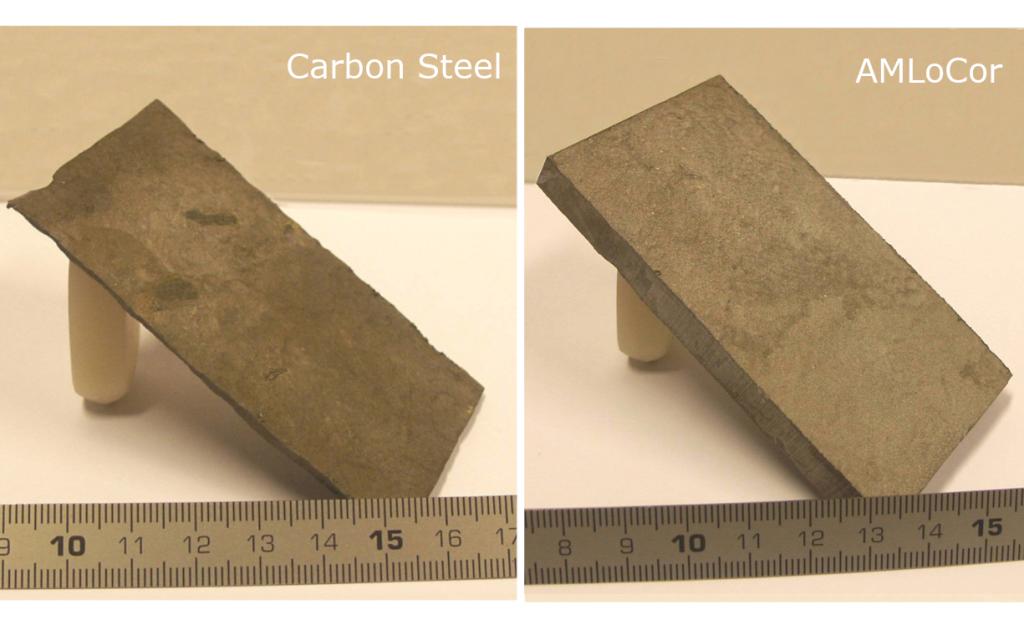

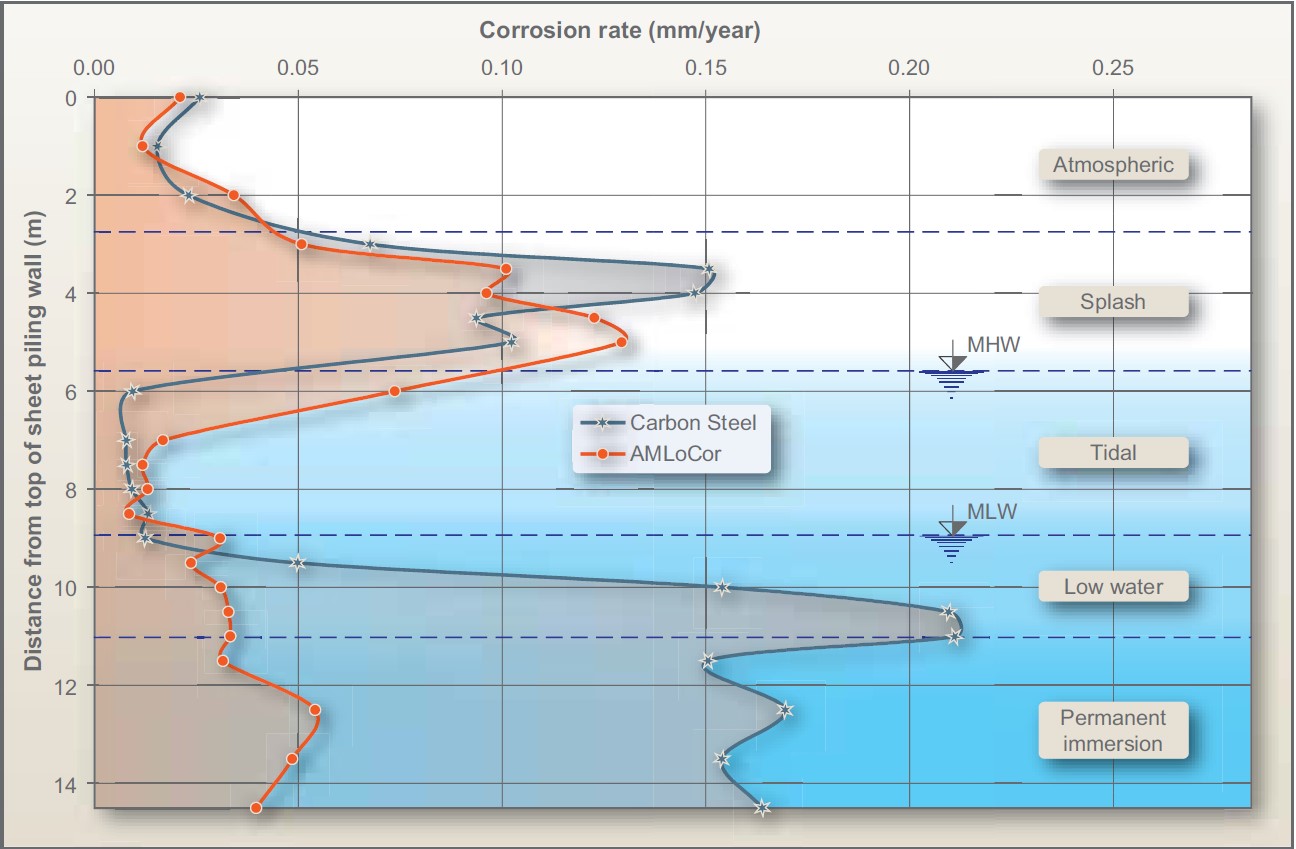

In-situ test specimens have proven that the loss of steel thickness of AMLoCor is reduced by a factor 3 to 5, depending on the exposed zones.

Corrosion

Corrosion is a natural electrochemical phenomenon affecting metals and metallic alloys like steel. It leads to transforming the iron atom in the steel into its original state, natural iron oxide (formation of a rust layer).

Coating layers prevent this chemical reaction simply by separating the steel surface from the electrolyte (water). The coating forms a barrier that reduces the transfer of reactants between the steel and the water. A dense and homogeneous rust layer on the steel surface can have a similar protective effect.

Cathodic protection works in a different way: the chemical reaction still occurs, but a less noble metallic element is introduced into the system and corrodes, instead of the steel (galvanic anodes of aluminium for instance), or an electrical system provides the required electrons to protect the steel. Corrosion is a very complex topic depending on a lot of different parameters, that will not be dealt with in more detail in this page.

For further information please contact us.

AMLoCor - Delivery, Properties, and Composition

Read about delivery conditions, mechanical properties, and chemical composition of AMLoCor steel sheet piling

Advantages of AMLoCor

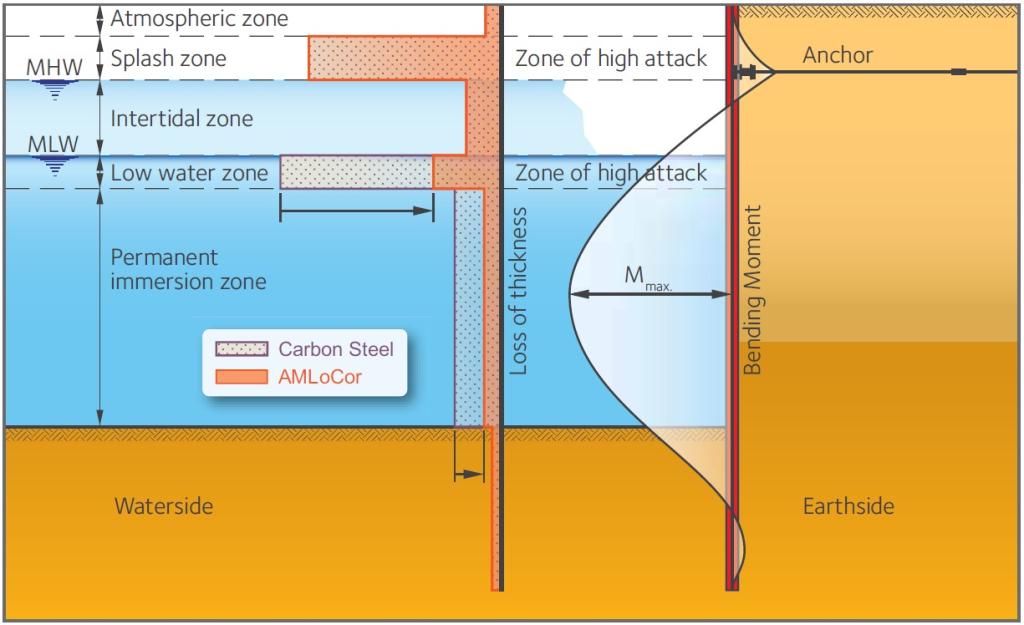

The main advantage of AMLoCor is a significant reduction of the corrosion rates in the Low Water Zone (LWZ) and in the Permanent Immersion Zone (PIZ).

For the verification of the structure, the designer considers average homogeneous corrosion, assuming that the loss of thickness is uniform all over the surface, as opposed to ‘pitting’ corrosion, which might have more local influence on the serviceability state.

In general, the maximum bending moments, and consequently the steel stresses, are in an area where corrosion rates are relatively low: permanent immersion zone or embedded zone (see Fig. 4). Yet the Low Water Zone sometimes governs the design, because in the permanent immersion zone the reduction of the section properties is offset by the lower thickness loss.

AMLoCor® is backed up with full scale and laboratory tests which have been performed during the last twenty years.

The chemical composition has been slightly improved all along those research projects in order to fulfill the requirements of the product, from durability to fabrication and welding. The excellent performance in the low water zone and in the immersion zone has been confirmed.

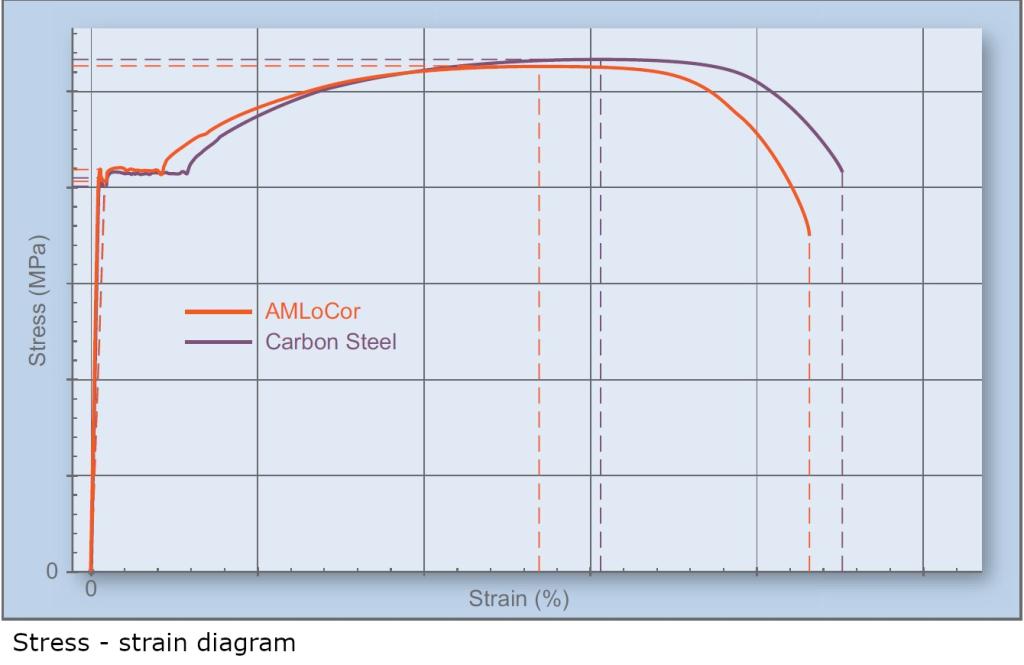

Although it is not a ‘standard’ carbon steel used in the construction industry, this micro-alloyed steel can be designed and installed based on standard design procedures and guidelines valid for steel sheet piles, for instance according to EN 1997, EN 1993 Part 5, EN 10248, EN 12063, EAU 2004, etc.

The design approach has to be adapted, to take into account the loss of steel thickness. The designer may consider a combination of additional protection methods for zones where the steel is less effective, including coatings, concrete capping beams, etc. AMLoCor steel grade is slightly more expensive per ton than carbon steel, due to the cost of the additional alloys, just like other special steels as ASTM A690. However the cost-efficiency of any solution needs to consider the overall investment during the whole service life. AMLoCor will in many cases yield the cheapest solution in the long-term.

In addition, AMLoCor protects steel from ALWC (Accelerated Low Water Corrosion) which is related to biological activity enhancing degradation of steel in the low water zone. The exact mechanism has not yet been scientifically identified, but some seaports in the UK and France have reported this issue.

Properties of AMLoCor

Design considerations

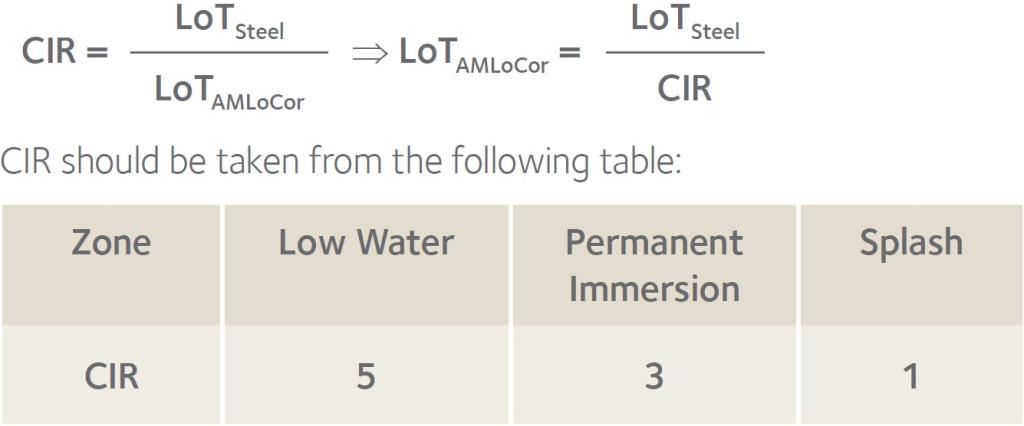

The use of cathodic protection (CP) can avoid any corrosion in the submerged zones: LWZ and PIZ, see Fig. 1. By contrast, if AMLoCor is used, loss of thickness (LoT) due to corrosion has to be considered, when designing the structure. The main difference is that LoT will be drastically reduced thanks to the use of AMLoCor when compared with an average carbon steel. For design purposes LoT data for classical steel grades in accordance with EN 10248: 1995 are available, either based on local experience or on recommendations and standards (EAU 2004, EN 1993-5: 2007).

From these, design LoT data for AMLoCor are obtained using the Corrosion Impediment Ratio (CIR)

Steel grades

Hot rolled and cold formed sheet pile sections

If limit state design is used, the following design verification approach is recommended:

- at ultimate limit state (ULS), design verification takes into account reduced design resistances Rd,cor due to corrosion loss of thickness over the whole structure: Ed ≤ Rd,cor

- at serviceability limit state, the structure is checked against perforation in every zone: LoT < minimum thickness.

As mechanical properties of AMLoCor grades are fully equivalent to normal piling grades, design structural resistances can be determined according to all relevant design codes used for steel sheet piling structures, like EN 1993-5:2007.

Provided the right filler material is used for welding, design verifications for welds also can be done according to these codes. For partial factor verification, it is worth noting, that due to the extreme care required during manufacturing of piling products in AMLoCor, scattering of properties is limited and partial factors for the material properties used for piling steel grades fully apply.

Cost comparison

Fabrication, connections, maintenance

The intrinsic properties of AMLoCor make it a ‘special’ steel grade with respect to welding. Specific welding procedures have been worked out to ensure state-of-the-art welding. Welders also have to be certified accordingly. The choice of the electrodes is important. Please contact us for more information on the different welding procedures.

Splicing and special piles can be based on EN 12063, except for the welding procedures. Welding procedures are referenced in the German General Technical Approval Z-30.10-55.

The C9 connectors are available in AMLoCor grade. For other special connectors in AMLoCor, please contact us.

In order to avoid damages to connecting devices it is important to design the connection carefully and ensure that the different elements from different steel grades are adequately protected.

One essential parameter is the contact surface of the different steel elements (bolts, walings, etc.).

In very unfavourable conditions, an insulated material at the interface between different elements may be recommended.

AMLoCor is compatible with all coating systems that can be applied on standard sheet piling steel grades. Galvanization is not recommended in combination with AMLoCor, as corrosion protection is already ensured by this steel grade. Coatings shall be compatible with cathodic protection, if CP is foreseen. From an economical point of view, combining AMLoCor with a CP may be a cost-effective solution in certain instances.

Sheet pile walls in AMLoCor do not need any specific maintenance. Depending on the design method used, a regular survey of the coatings and residual thickness of sheet piles is highly recommended.

Installation

Services

The expertise of the engineers of our technical department allowed us to become a reference for many design engineers, project owners and contractors seeking professional advice. Our skilled engineers will assist you with any technical issue, free of charge. If you need a welding procedure, or guidance on fabricating special sheet piles, on sealants, on design, layout drawings, etc, do not hesitate to contact us.

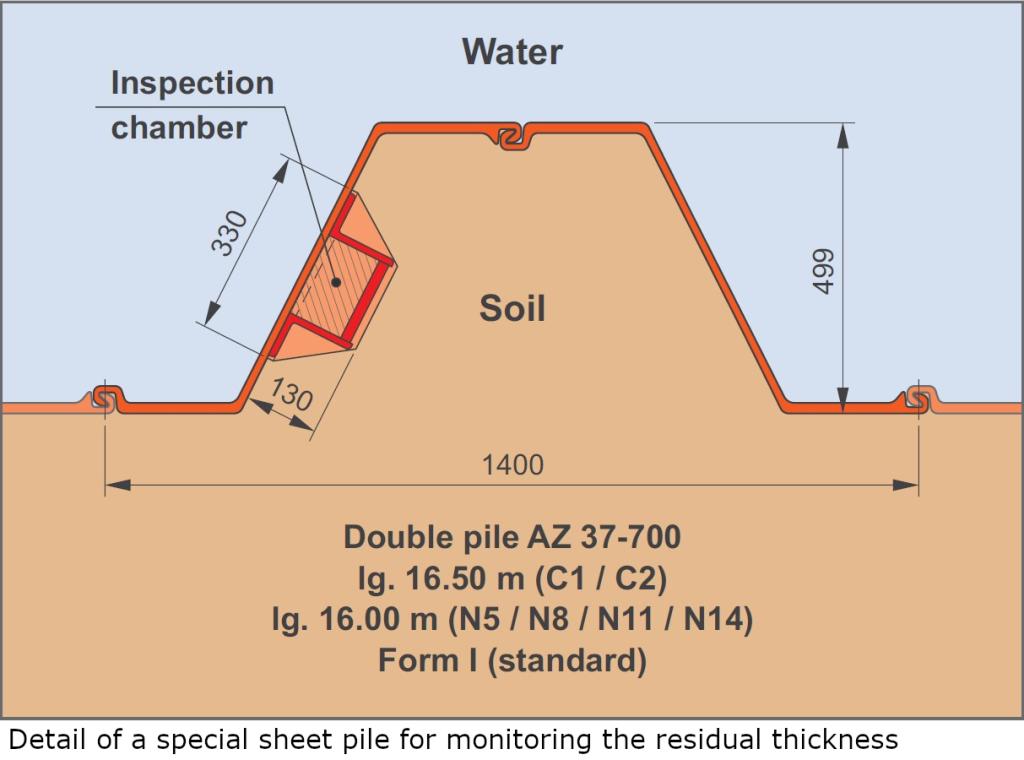

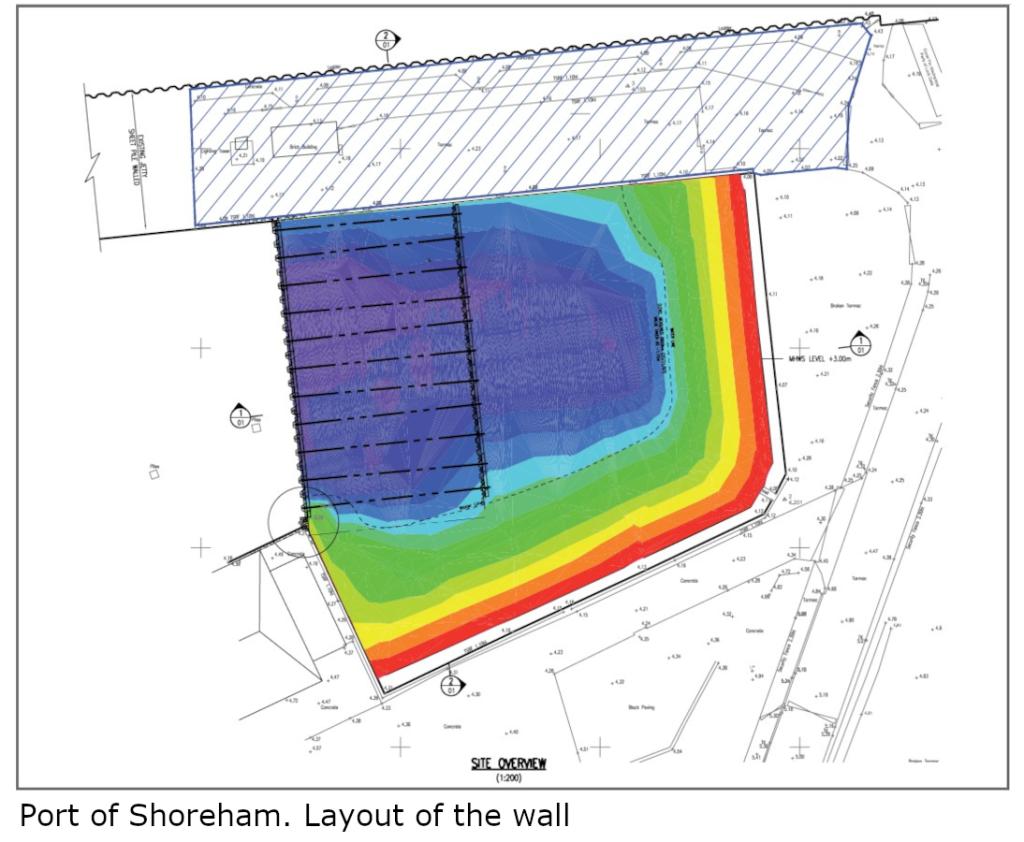

The longevity of AMLoCor is key and being tested in different ports. Our Research and development department has created a special measuring device to allow the measurement of the residual thickness at different levels along a structure. This requires special sheet piles being fabricated beforehand and installed as part of the quay wall.

A manhole on the quay wall surface allows the introduction of the device behind the sheet pile wall. Traditional inspection methods (ultra sonic sensor), performed from the waterside, require cleansing of the rust layer. Corrosion products are removed, thus activating the steel surface. As a result, corrosion is reinitialized and measurement campaigns are distorted. The new developed method will yield more accurate results and will not damage the corrosion products. Measurements can be done every year, over a period of minimum five years. Our R&D department can assist project owners with this type of additional survey of the structure.

ArcelorMittal can also help with the elaboration of a tender specification for AMLoCor steel grades.

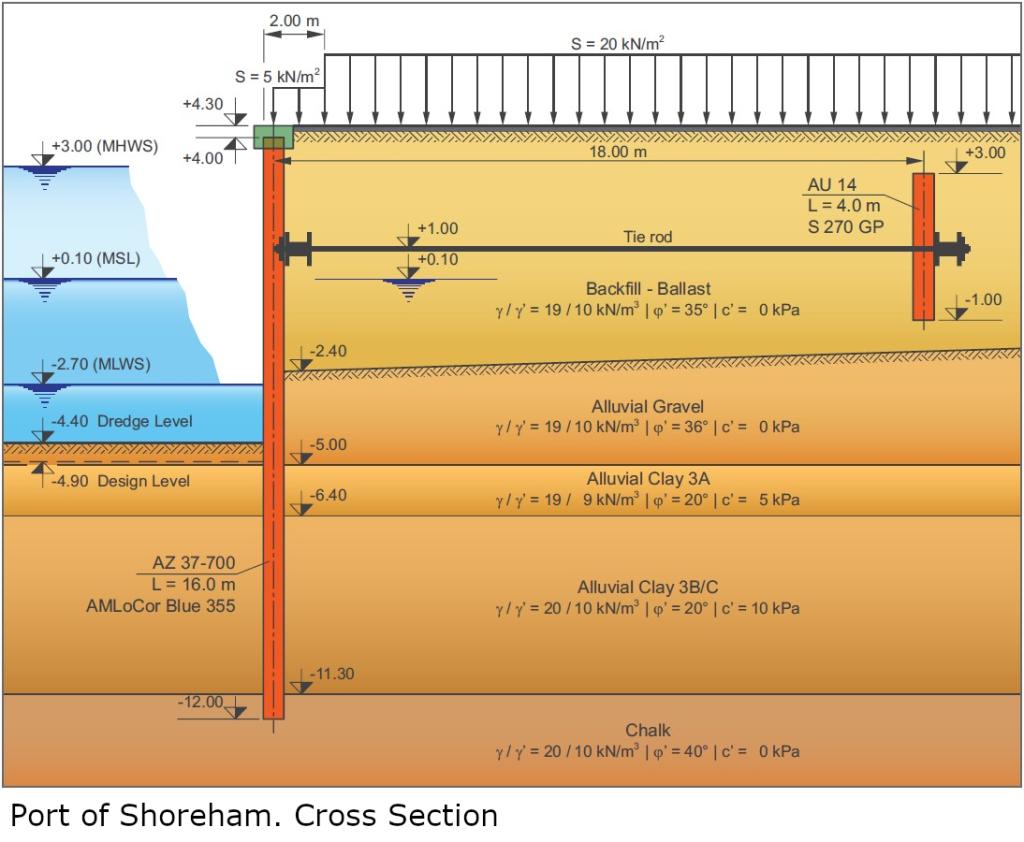

Reference case: Port of Shoreham, UK

Protecting Shoreham from the risk of flooding

Shoreham adur tidal walls flood defence scheme. Shoreham | UK

Disclaimer

The data and commentary contained within this steel sheet piling document is for general information purposes only. It is provided without warranty of any kind. ArcelorMittal Commercial RPS S.à r.l. shall not be held responsible for any errors, omissions or misuse of any of the enclosed information and hereby disclaims any and all liability resulting from the ability or inability to use the information contained within.

Anyone making use of this material does so at his/her own risk. In no event will ArcelorMittal Commercial RPS S.à r.l. be held liable for any damages including lost profits, lost savings or other incidental or consequential damages arising from use of or inability to use the information contained within. Our sheet pile range is liable to change without notice.