Download center

Here you can find all our documents by different categories

Highlights

Your request has generated 136 records «» :

Tech info, Environment

Implementation of environmental criteria in civil engineering (infrastructure)

Applying Environmental Criteria in Civil Engineering

Learn more

Tech info, Ports

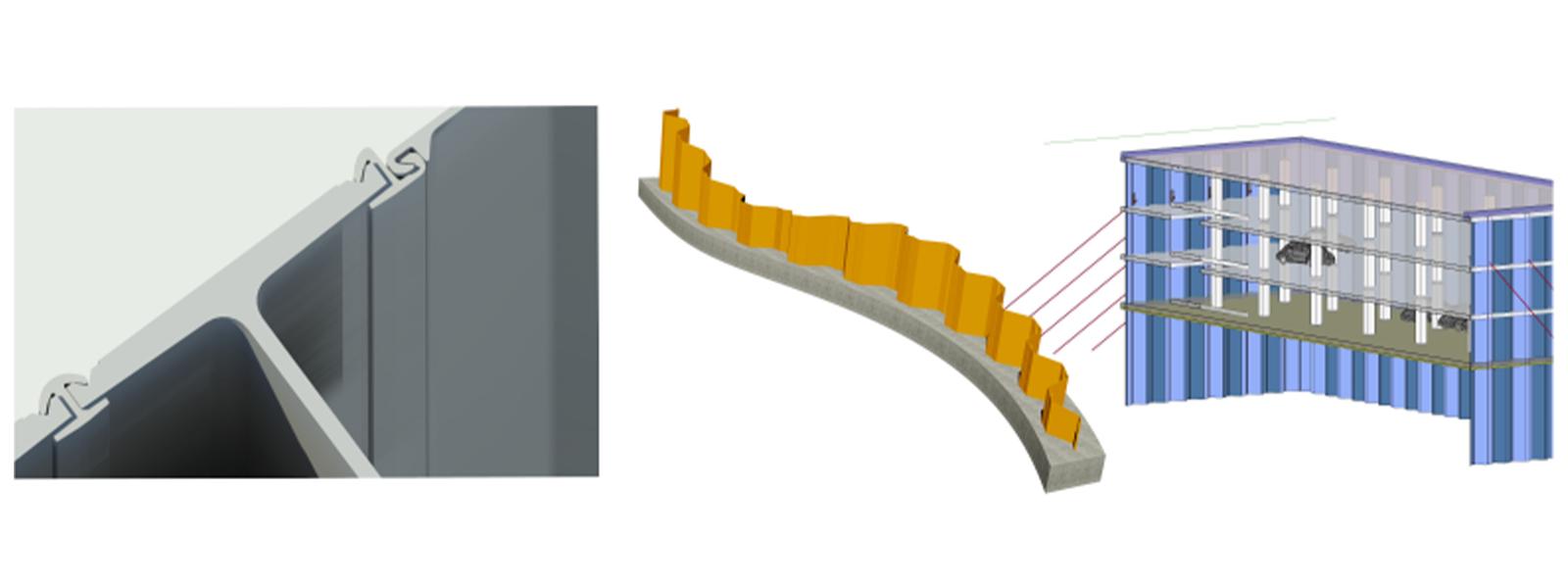

Seismic design of sheet piles. Brochure | 2021

Innovative Seismic Design Solutions for Sustainable Sheet Piling Infrastructure

Learn more

Articles, Ports, HP Piles

The Environmental Impact of Steel Sheet Pile Structures

Case Study by João MARTINS (ArcelorMittal Commercial RPS Sàrl - Luxembourg)

Learn more

Case Study, Flood, Z-Piles

Manalapan Seawall & Storm Protection, FL, USA | 2016

Storm Protection/Erosion Control Palm Beach

Learn more

BIM & CAD files

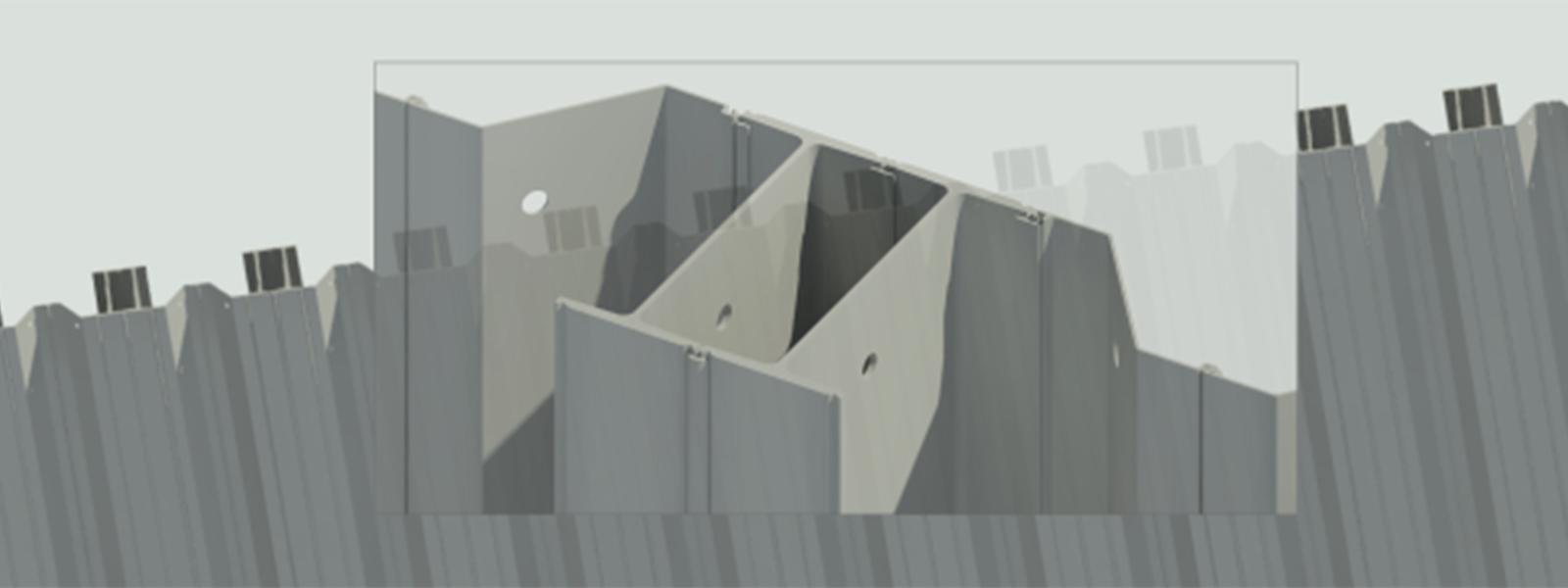

AutoCad® files .dxf

The full range of ArcelorMittal's steel sheet piles in the format .dxf

Learn more

BIM & CAD files

AutoCad® files .dwg

The full range of ArcelorMittal's steel sheet piles in the format .dwg

Learn more