Underground Car Parks

This study examines the use of steel sheet pile (SSP) walls in the construction of underground parking facilities, focusing on their effectiveness in different regional conditions. The first part compares various wall construction methods for a two-level underground parking project in northern Germany, evaluating factors like cost, construction speed, and sustainability. The second part highlights the advantages of SSP walls in the Netherlands, specifically addressing their suitability for soft soil and high groundwater conditions. Both sections emphasize the efficiency, cost-effectiveness, and environmental benefits of steel sheet piles as an ideal solution for underground parking structures.

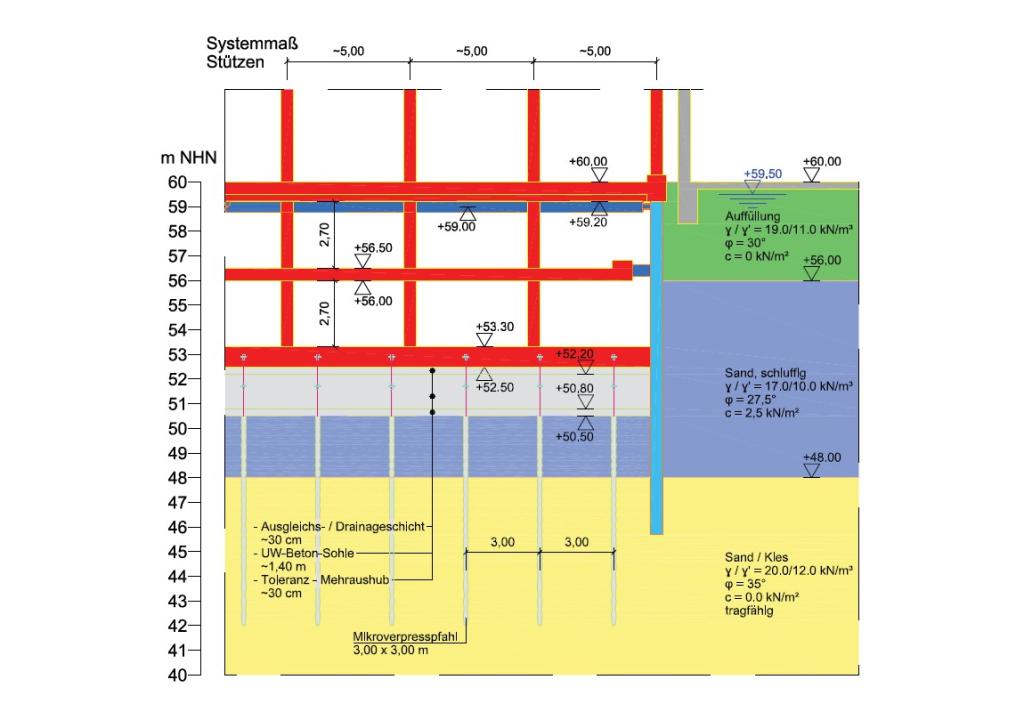

The study "Underground Parking with Steel Sheet Piles – A Comparative Study," commissioned by ArcelorMittal and conducted by GRBV Ingenieure im Bauwesen, compares various methods for constructing the outer wall of a two-level underground parking facility. The research focuses on typical northern German soil conditions and an inner-city location with adjacent buildings. It evaluates several wall construction methods based on cost, efficiency, and factors such as construction time, logistics, and sustainability.

Cost Comparison: The study compares four construction variants:

- V1: Permanent sheet pile wall (SPW)

- V2: Temporary sheet pile wall (SPW t.)

- V3: Secant pile wall (BPW)

- V4: Diaphragm wall (SLW)

The sheet pile wall (V1) emerged as the most cost-effective solution, priced at €1.15 million—25% cheaper than the secant pile wall and 39% cheaper than the diaphragm wall.

Total Project Costs: For the complete underground parking construction, costs ranged from €3.1 million (sheet pile wall) to €3.6 million (diaphragm wall).

Construction Speed: Steel sheet pile solutions are found to be twice as fast as other materials, making them a favorable option for reducing project duration.

Other Evaluation Criteria: Additional factors considered include:

- Usable floor area (important for revenue generation)

- Maintenance costs

- Execution risks

- Sustainability

The study underscores the significant advantages of using steel sheet piles for underground parking construction, particularly in terms of cost-effectiveness and construction speed. The sheet pile wall (SPW) proved to be the most efficient solution, both financially and practically.

The study highlights the advantages of using steel sheet pile (SSP) walls for constructing underground car parks (UCP) in the Netherlands, particularly emphasizing their effectiveness in the region's soft soil and high groundwater conditions.

Why Choose Steel Sheet Pile Walls?

- Dual Functionality: SSP walls serve as both retaining walls and foundations, reducing the need for internal columns and maximizing available space.

- Cost and Time Efficiency: SSP walls are up to 50% cheaper and can reduce construction time by half compared to alternative methods.

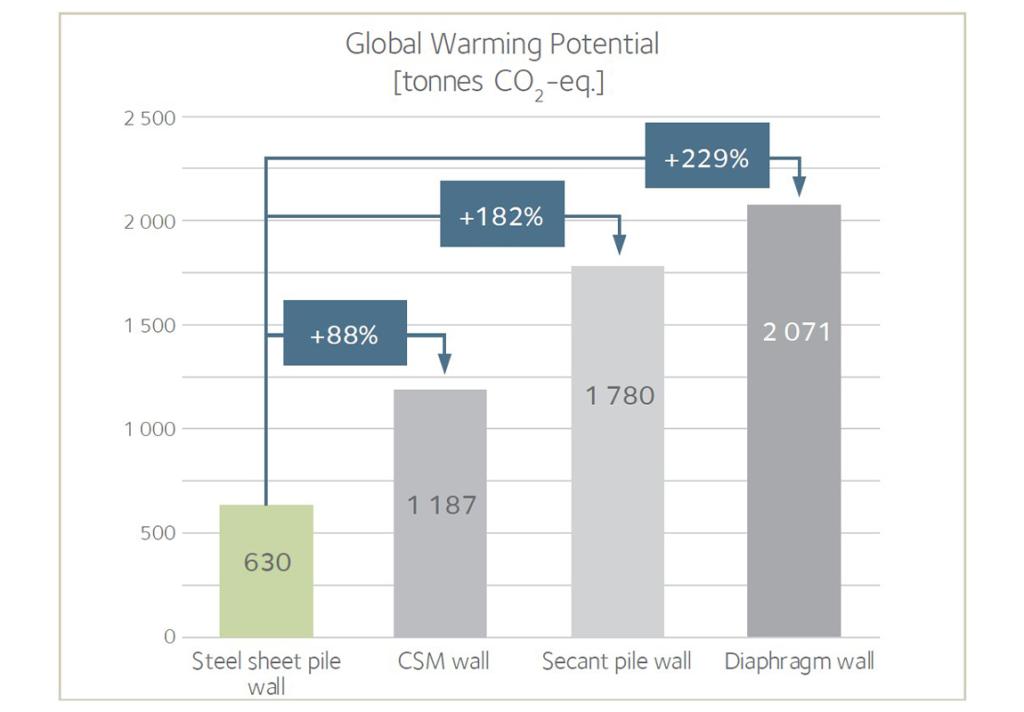

- Environmental Benefits: SSP walls significantly lower the carbon footprint, with emissions up to 88% less than concrete alternatives.

Comprehensive Study of SSP Walls:

- Sustainability & Efficiency: SSP walls are identified as the most sustainable and efficient solution for UCPs with 1 to 4 levels below ground, performing effectively in Dutch soil and high groundwater conditions.

- Construction Speed: SSP walls are installed up to twice as fast as other methods.

- Reduced Traffic Congestion: Using SSP walls in city centers results in fewer trucks delivering materials, reducing traffic congestion and minimizing disturbances to neighbors.

Cost Analysis:

- Cost-Effectiveness: The pressed-in sheet pile retaining wall is the most cost-effective solution, offering low costs, fast execution, and high-quality watertightness.

- Other Alternatives: The D-Wall is more expensive and too heavy for a two-level car park, while secant pile and SoilMix walls are unsuitable for sandy soil with shallow groundwater.

Life Cycle Assessment (LCA):

- Lower Carbon Footprint: SSP walls have a significantly lower carbon footprint than concrete alternatives (diaphragm wall, secant pile wall) and cutter soil mix walls, with a minimum emissions reduction of 88%.

In conclusion, steel sheet pile walls provide a highly efficient, cost-effective, and environmentally friendly solution for underground car park construction in the Netherlands, with notable advantages in terms of construction time, sustainability, and space optimization.