Underground car parks – Life Cycle Assessment – new brochure

Underground car parks (UCPs) have been built in many countries around the world, but the Netherlands stands out from the other countries with a large number built in the last decade. Steel sheet piles used in UCPs have proven their cost-efficiency, but what about their environmental footprint? To improve the eco-design of its sheet pile range, ArcelorMittal launched in 2018 a project targeting the Netherlands with the objective of comparing different types of alternatives to build the surrounding walls of an UCP or a basement.

The first step was to hire Witteveen + Bos, a Dutch design engineering firm, to design four alternatives and to analyse the technical and financial criteria of each solution. The case study consisted of an underground car park , approximately 250 m by 30 m, with two levels, built in the region of Amsterdam, with a capacity of 600 cars. The conclusion of this study is that the steel sheet pile wall is 38 % more cost-effective than the Cutter Soil Mix (CSM) wall, and even more compared to the Secant Pile wall and the Diaphragm wall. The outcome of this study is explained in detail in our dedicated brochure (see link below).

Environmental impact will be one of the key factors to select the most sustainable solution to be built, and to tackle this topic, the Life Cycle Assessment is a fair and transparent method to compare different solutions. This task was performed by our R&D department and peer-reviewed by an environmental expert from TNO in the Netherlands, an independent institute. To be consistent, the LCA used EPDs from the same EPD program holder (IBU e.V.).

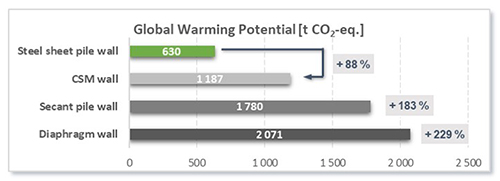

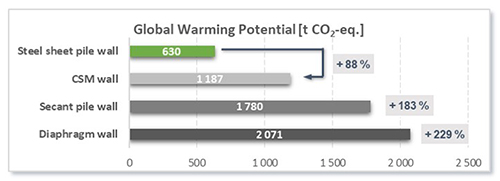

The findings of the base scenario of this specific case study show that the carbon footprint, expressed as the Global Warming Potential (GWP), of the steel solution is 88 % lower compared to the Cutter Soil Mix wall, and even more compared to the other alternatives. This corresponds to a saving of 557 tonnes of CO2-eq.

The first step to improve the eco-design of steel sheet piles is to use renewable energy in the Electric Arc Furnace (EAF) to produce steel from scrap, thus reducing by 30 % the GWP (based on the EPD EcoSheetPile™ Plus).

LCA of a an underground car park - case study - NL

LCA of a an underground car park - case study - NL

Download the brochure for more details on this LCA study or go to our dedicated webpage (see links below).

The first step was to hire Witteveen + Bos, a Dutch design engineering firm, to design four alternatives and to analyse the technical and financial criteria of each solution. The case study consisted of an underground car park , approximately 250 m by 30 m, with two levels, built in the region of Amsterdam, with a capacity of 600 cars. The conclusion of this study is that the steel sheet pile wall is 38 % more cost-effective than the Cutter Soil Mix (CSM) wall, and even more compared to the Secant Pile wall and the Diaphragm wall. The outcome of this study is explained in detail in our dedicated brochure (see link below).

Environmental impact will be one of the key factors to select the most sustainable solution to be built, and to tackle this topic, the Life Cycle Assessment is a fair and transparent method to compare different solutions. This task was performed by our R&D department and peer-reviewed by an environmental expert from TNO in the Netherlands, an independent institute. To be consistent, the LCA used EPDs from the same EPD program holder (IBU e.V.).

The findings of the base scenario of this specific case study show that the carbon footprint, expressed as the Global Warming Potential (GWP), of the steel solution is 88 % lower compared to the Cutter Soil Mix wall, and even more compared to the other alternatives. This corresponds to a saving of 557 tonnes of CO2-eq.

The first step to improve the eco-design of steel sheet piles is to use renewable energy in the Electric Arc Furnace (EAF) to produce steel from scrap, thus reducing by 30 % the GWP (based on the EPD EcoSheetPile™ Plus).

Download the brochure for more details on this LCA study or go to our dedicated webpage (see links below).

Last modified: November 26, 2021

Date publish: November 26, 2021

Related links

Downloads

Français

Français Deutsch

Deutsch Italiano

Italiano